traditional rubber accelerator for rapid curing etu-80 in brazil

The behavior of dithiocarbimate derivative as safety

The behavior of dithiocarbimate derivative as safety accelerator of natural rubber compounds Article (Available) in Journal of Applied Polymer Science 110(4):1938 - 1944 · November 2008 with ...

Send Inquiry

Rubber Accelerator Tetramethylthiuram Disulfide TMTD-80

Tetramethylthiuram Disulfide TMTD-80 TT-80Rubber accelerator Pre-disperse Masterbatch TT-80 TMTD-80 TMTD-80, TT-80 commonly used along...

Send InquiryWESTCO™ CBS Accelerator for Rubber

WESTCO™ CBS Accelerator N-cyclohexyl-2- benzothiazole sulfenamide CAS# 95-33-0 WESTCO™ CBS is a delayed action sulfenamide accelerator suitable for natural rubber and synthetic rubber. It has the ability to provide fast efficient mixing without scorching or sacrificing physical properties.

Send InquiryThe behavior of dithiocarbimate derivative as safety

ZNIBU gives a small scorch time, similar to similar crosslink density despite the accelerator TMTD, but the optimum cure time and cure rate used. index for the two compounds are completely differ- Combinations of accelerators are frequently used ent.

Send InquiryInstant Adhesives - Henkel Adhesives

LOCTITE ® Instant adhesives are one-part, room-temperature curing adhesives available in a wide range of viscosities. They are typically used for high-performance bonding of numerous materials in just seconds – rubber, wood, metal and even the latest generation plastics.

Send Inquiry

RubbeR TesTing - TA Instruments

The TA instruments RPA elite Rubber Process Analyzer (RPA) is the most advanced rotorless rotational shear rheometer dedicated to the complete characterization of polymers, rubber and rubber compounds at all stages of manufacture. The RPA elite provides invaluable viscoelastic data on materials that are uncured, through the curing process, and in situ cured materials.

Send Inquiry

Study of the compatibility of nitrile rubber

Linhares and Furtado reported the effect of B2 biodiesel on nitrile rubber and found that no major degradation of the nitrile rubber samples occurred after exposure to a diluted form of biodiesel. Despite the potential for bio-fuel production in Brazil, few studies have examined the compatibility between engine parts and the most commonly produced biodiesel in Brazil.

Send Inquiry

SOLID AND LIQUID SILICONE RUBBER - MATERIAL AND PROCESSING

Why silicone rubber is inherently different from other elastomers 1.2 Major Classes of Silicone Rubber 9 How solid and liquid silicone rubber grades differ, and what characterizes them 1.3 Components of Silicone Rubber 10 Fillers, additives and catalysts, and their role in formulation 1.4 Curing 12

Send Inquiry

Elastomer Engineering Guide

South America, particularly Brazil, was the prime source of natural rubber until the early 1900s. Then, British Asian colonies, using rubber trees from seeds smuggled out of the Amazon basin, began to compete with traditional sources. The period between World Wars I and II witnessed the first development of a true

Send InquiryInternal Linings for Vessels and Tanks - NACE Jubail

NACE TM0185 Rapid Decompression Typical Test Program: 100 bar (1450 psi) Reduced to 50 bar (725 psi) in 5 minutes Then reduced to atmospheric in a further 10 minutes Recommended 5 bar/min Performance Testing – Depressurisation Resistance

Send InquiryWESTCO™ ETU Accelerator for Rubber

WESTCO™ ETU Accelerator (Ethylene Thiourea) CAS# 96-45-7. WESTCO ™ ETU is an ultra-accelerator for polychloroprene rubber. It is also used in latex as a primary accelerator. It is active even at low temperatures. WESTCO ™ ETU can be used without zinc oxide for transportation articles. It is an antioxidant in adhesive systems. Packaging: 25 kg. bag.

Send Inquiry

WESTCO™ ETU 80 Accelerator for Rubber

WESTCO™ ETU 80 Accelerator Your long term partner for all your rubber chemical and additives needs.

Send InquiryRubber Accelerator for Rapid Curing ETU-80 China Manufacturer

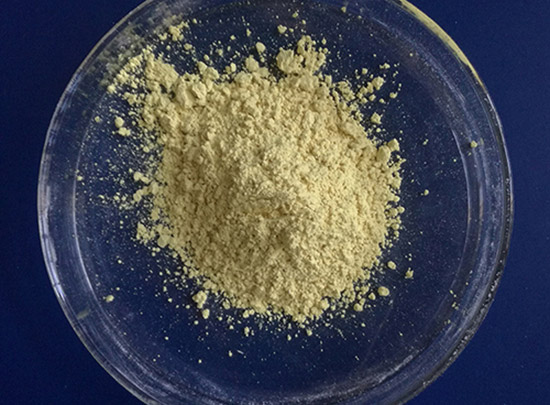

Accelerator for rapid vulcanization rubber ETU TRA. 1.Product composition: Approx. 80 wt% Ethylene thiourea (ETU/NA-22) CAS No.: 96-45-7 EINECS No.: 202-506-9 Approx. 20 wt% polymer binder and dispersing agent . 2. Application: Accelerator for rapid vulcanization of chloroprene rubber and other diene rubbers, particularly CR, EPDM, ECO and CM.

Send InquiryWESTCO™ TMTD Accelerator for Rubber

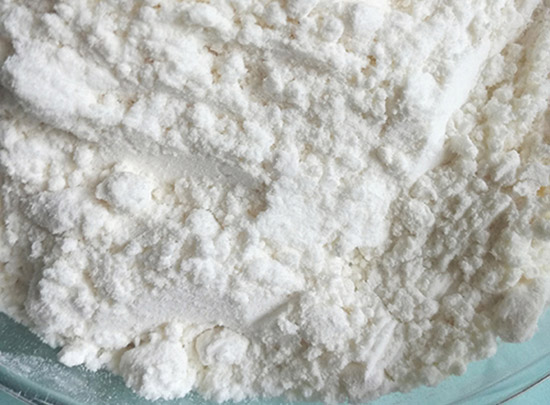

WESTCO™ TMTD is the most widely used among ultra-accelerators in natural and synthetic rubber; acts as a retarder for CR; an effective accelerator for low temperature cures. Applications: Rubber curing accelerator with super anti-scorching and short curing time features. Used in manufacture of tires, shoes, tubes, cable, etc.

Send InquiryWESTCO™ ZBPD Accelerator for Rubber

WESTCO™ ZBPD is a non-staining, non-blooming liquid, fast curing secondary accelerator for rubber compounds, especially EPDM and NR. It may be used with standard rubber accelerators but is most commonly used along with other non-nitrosamine generating accelerators. When used with sulfonamides in NR, it improves reversion resistance.

Send Inquiry

New-generation curative taking an ETU replacement

Ethylene thiourea (ETU) is an accelerator which has been widely used for many years in polychloroprene and epichlorohydrin rubber compounding to produce fast-curing, heat- resistant compounds that process well.

Send Inquiryacceleratorsand acceleratorsystems

The use of sulfur alone for curing is both time consuming and inefficient. A typical cure with sulfur alone will use 5-20 phr (parts per hundred rubber) sulfur and require 5-15 hours to complete at 266-320°F. This is a result of the slow reaction between the rubber and large number of sulfur atoms to form the crosslinks.

Send Inquiry

The behavior of dithiocarbimate derivative as safety

The behavior of dithiocarbimate derivative as safety accelerator of natural rubber compounds Article (Available) in Journal of Applied Polymer Science 110(4):1938 - 1944 · November 2008 with

Send Inquiry