the best rubber accelerator(materials) in laos

Vulcanization & Accelerators

between sulfur and the Rubber Hydrocarbon occurs mainly aC (doublet the C = bonds ) and each crosslink requires 40 to 55 sulphur atoms (in the absence of accelerator). The process takes around 6 hours at 140°C for completion, which is uneconomical by any production standards. The vulcanizates thus produced are

Send InquiryAccelerator | rubber manufacturing | Britannica

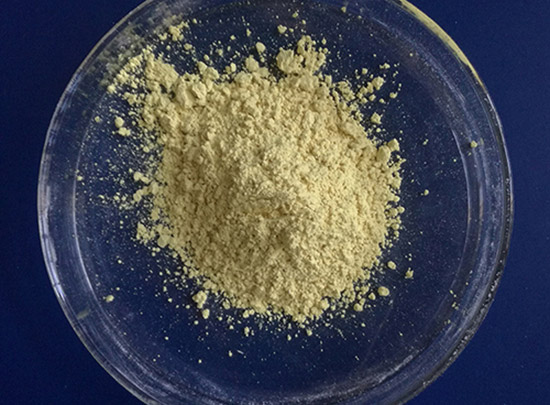

Accelerator, in the rubber industry, any of numerous chemical substances that cause vulcanization (q.v.) of rubber to occur more rapidly or at lower temperatures. Many classes of compounds act as accelerators, the most important being organic materials containing sulfur and nitrogen, especially derivatives of benzothiazole.

Send Inquiry

Styrene Butadiene Rubber - SBR - Techno Ad

Styrene-Butadiene, which is a copolymer of styrene and butadiene, is the most widely used synthetic rubber in the world. SBR is also known as Buna S, from the trade name by Bayer, and GR-S (Government Rubber Styrene). SBR rubber is used primarily in the manufacturing of tires by blending it with natural rubber and butadiene rubber. SBR is considered weak and unusable, but when reinforced with carbon black it is strong and abrasion resistant.

Send InquiryRUBBER CHEMISTRY - Läroverket i Småland AB

chemical and physical transverse bonds between rubber macromolecules resulting in a spatial vulcanizate mesh, giving unique properties to the material. Various chemical - vulcanizing - agents are used to create the chemical transverse bonds between rubber macromolecules (such as sulphur, peroxides, metal oxides, resins,

Send Inquirytop quality rubber accelerator for rubber belts of liberia

Rubber Accelerator - Rubber Accelerator Distributor, Supplier. Since inception, we have emerged as a prolific supplier of Rubber Accelerator. Sourced from some of the authentic vendors of the market, these products are processed from top quality compounds in-sync with the globally laid quality standards.

Send InquiryPolyvinyl siloxane impression materials: An update

share of the impression material market. Polyvinyl siloxanes have applications in fixed prosthodontics, operative dentistry, removable prosthodontics and implant dentistry.1,2 The materials are presented in the form of two pastes (a base and an accelerator) which can be hand spatulated or autodispensed from

Send Inquiry

Nitrile vs Latex vs Vinyl Gloves: What's Right for You

The newest option on the market is Nitrile gloves, or also known as Buna-N, Perbunan, acrylonitrile butadiene rubber, or NBR, to scientists. Nitrile gloves are a synthetic rubber copolymer that mimics the feel and fit of latex, without using natural resources.

Send Inquiry10 Best Glue for Shoes in 2019 [Review & Guide] - ShoeAdviser

Gorilla Original Glue. The glue is versatile and can be used for any type of footwear, it will bond to any kind of material making it best for your leather, vinyl, canvas or rubber soles. It works by expanding into the materials to create a very strong bond. The glue is water activated polyurethane.

Send InquiryThe Best Bedding for Allergies - Health

The Best Anti-Allergy Bedding. 12 anti-allergy bedding essentials for a sneeze-free night's sleep. Allergy sufferers, listen up: your bedroom may be the source of your sniffles. Dust mites are the most common cause of allergies from house dust, according to the American College of Allergy, Asthma, and Immunology.

Send Inquiry

TEST METHODS OF RUBBER MATERIALS AND PRODUCTS

Chapter “Rubber Compound and Vulcanizate Testing” is related to the chapter on “Rubber Raw Material Testing” and provides a comprehensive description of the system of testing rubber compounds, materials and vulcanizates, starting from sampling and testing vessels up to evaluation of test results according to specific standards.

Send InquiryVulcanization & Accelerators

between sulfur and the Rubber Hydrocarbon occurs mainly aC (doublet the C = bonds ) and each crosslink requires 40 to 55 sulphur atoms (in the absence of accelerator). The process takes around 6 hours at 140°C for completion, which is uneconomical by any production standards. The vulcanizates thus produced are

Send InquiryRubber Accelerators List / Manufacturers

Western Reserve Chemical offers a full range of rubber accelerators to increase the speed of the vulcanization of rubber. We supply both primary and secondary accelerators that are suitable for both for natural rubber and synthetic rubber compounds including NR, CR, SBR, NBR, BR, EPDM and chlorobutyl rubber.

Send Inquiry

Accelerator | rubber manufacturing | Britannica

Accelerator, in the rubber industry, any of numerous chemical substances that cause vulcanization (q.v.) of rubber to occur more rapidly or at lower temperatures. Many classes of compounds act as accelerators, the most important being organic materials containing sulfur and nitrogen, especially derivatives of benzothiazole.

Send InquiryStyrene Butadiene Rubber - SBR - Techno Ad

Styrene-Butadiene, which is a copolymer of styrene and butadiene, is the most widely used synthetic rubber in the world. SBR is also known as Buna S, from the trade name by Bayer, and GR-S (Government Rubber Styrene). SBR rubber is used primarily in the manufacturing of tires by blending it with natural rubber and butadiene rubber. SBR is considered weak and unusable, but when reinforced with carbon black it is strong and abrasion resistant.

Send Inquiry

Products - Jim Chemical Pvt, Ltd.

It gives vulcanizates with good ageing properties, but tends to stain white rubber. Inhalation of the dust should be avoided. It is a non-discolouring accelerator for use in Neoprene (CR) latex, Natural Rubber, EPDM sponge applications and many other elastomers. It provides rapid acceleration and can be used in latex and cement applications.

Send Inquiry

“Rubber Process Analyzer –RPA. Bridging the gap between

Rubber compound process troubleshooting Rubber compound extrusion. Serious processing problem in production Summary of observations: • All batches passed standard QC tests. • QC test involves rheometer only (MDR). • One batch gave higher extrusion head pressure and temperature,

Send Inquiry

Nitrile vs Latex vs Vinyl Gloves: What's Right for You

When it comes to choosing gloves, it can be an overwhelming decision. Afterall, if your profession requires you wear them daily, you'll want the best for your hands. There are many options for glove material. Do you go with nitrile, latex, or vinyl? Are there even major differences between them? There are many things

Send Inquiry

Rubber Accelerators - Rubber engineering - Eng-Tips

GrahamBennett (Materials) 14 Sep 15 14:33 OK, thanks for the explanation. All sulfenamides breakdown at faster or slower rates to give MBT, which is the active accelerator.

Send Inquiry