high quality liquid silicone rubber manufacturing process in malaysia

SOLID AND LIQUID SILICONE RUBBER - MATERIAL AND PROCESSING

Uncured silicone rubber contains polymers of different chain lengths. It always comprises a principal silicon-oxygen chain (the siloxane backbone) and an organic moiety bound to the silicon. A silicon atom has four valence electrons, which is why silicone rubber is often abbreviated with a Q for 鈥渜uaternary group鈥? The properties of

Send Inquiry

Liquid Injection Molding (LIM) - ASH庐 Industries

The most common material used in the LIM process is liquid silicone rubber. It's a high-purity platinum core silicone that's able to create the highly durable parts that are utilized in so many industries. For example, liquid silicone rubber is especially cherished in the medical industry, as tools and instruments made from the material are biodegradable, well made and reduce the risk of contamination.

Send Inquiry

Liquid Silicone Rubber Injection Molding vs High

LSR consists of liquid silicone material that has a very low viscosity, which allows the material to be cast into rubber sheets or injection molded. Raw uncured material for LSR consists of Part A and Part B, liquid components that the fabricator mixes, which starts the curing process. The application of heat accelerates the curing process.

Send Inquiry

Dongguan Tian'an Silicone Technology Co., Ltd.

Dongguan Tian'an Silicone Technology Co., Ltd. was founded in 2008. It is a state-level high-tech enterprise integrating R&D, production and sales of organic HTV silicone rubber, liquid silicone rubber, silicone oil and special additives for silicone gel.

Send InquiryInjection Molding Prototypes - Elastomer Technologies

Pour molding of room-temperature-vulcanizing (RTV) silicone 鈥?This process is used to create mockups or rough working prototypes from a material with properties that do not compare to those of liquid silicone or high-consistency rubber (HCR) silicone.

Send InquiryCable Accessories | Dow Inc.

Liquid silicone rubber elastomers from Dow help create medium to high voltage distribution materials: cable end terminations, cold-shrink splices, and adapters.

Send InquiryMedical Technology - Wacker Chemie AG

Injection molding is currently the most popular and efficient method of producing large quantities of silicones in consistently high quality. Liquid and solid grades of SILPURAN 庐 /ELASTOSIL 庐 silicone rubber can each be used in the production of seals, membranes and valves 鈥?the process is fully automatic.

Send Inquiry

Liquid Silicone Rubber (LSR) Mold Manufacturing

4-cavity duckbill with in-mold slitting. Liquid Silicone Rubber is a crosslinked (rubber) silicon-based elastomer, reinforced with unique filler systems, that provides outstanding properties. It offers a unique combination of chemical and mechanical properties thermoplastic elastomers (TPRs and TPEs) cannot match.

Send InquiryHow is Silicone Made? | SIMTEC

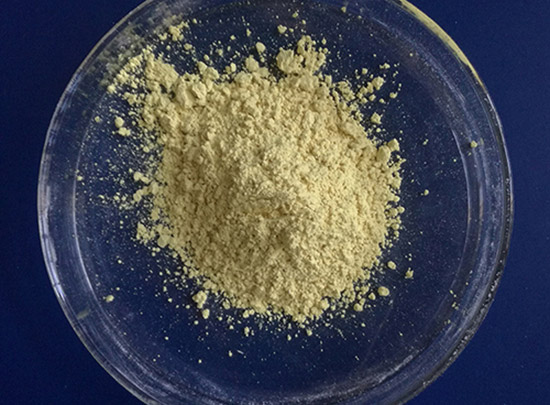

A Step-by-Step Guide to the Production of Silicone. To make silicone, this fine silicon powder is combined with methyl chloride and heated once again. The heat triggers a reaction between the two components, forming what is known as methyl chlorosilane. Methyl chlorosilane is actually a mix containing several compounds, the most predominant of which,...

Send InquiryBryant Rubber

Bryant Rubber is a complete engineering and manufacturing resource for the development and supply of a wide range of rubber-to-metal and rubber-to-plastic components, from standard mold-in-place gaskets to complex multi-material sealing systems.

Send InquirySOLID AND LIQUID SILICONE RUBBER - MATERIAL AND PROCESSING

Uncured silicone rubber contains polymers of different chain lengths. It always comprises a principal silicon-oxygen chain (the siloxane backbone) and an organic moiety bound to the silicon. A silicon atom has four valence electrons, which is why silicone rubber is often abbreviated with a Q for “quaternary group”. The properties of

Send Inquiry

Liquid Silicone Rubber Manufacturing Process

Injection molding of liquid silicone rubber (LSR) is a process to produce pliable, durable parts in high volume. Liquid silicone rubber is widely used in tod...

Send Inquiry

Dongguan Tian'an Silicone Technology Co., Ltd.

Dongguan Tian'an Silicone Technology Co., Ltd. was founded in 2008. It is a state-level high-tech enterprise integrating R&D, production and sales of organic HTV silicone rubber, liquid silicone rubber, silicone oil and special additives for silicone gel.

Send InquiryRubber Molded Products Manufacturing Process - Industrial

Liquid silicone rubber is a high purity platinum cured silicone with low compression set, great stability and ability to resist extreme temperatures of heat and cold ideally suitable for

Send InquiryLiquid Injection Molding (LIM) - ASH® Industries

Liquid Injection Molding (LIM) Liquid injection molding, or LIM, is a production process commonly used to make rubber parts or to make parts that need to withstand extreme conditions, regardless of the industry. The process is an injection molding process at heart, meaning that materials are injected into a pre-made mold,...

Send InquiryMedical Technology - Wacker Chemie AG

Injection molding is currently the most popular and efficient method of producing large quantities of silicones in consistently high quality. Liquid and solid grades of SILPURAN ® /ELASTOSIL ® silicone rubber can each be used in the production of seals, membranes and valves – the process is fully automatic.

Send Inquiry