the best vulcanization of rubber|springerlink in liberia

Thermal analysis applied to studying the influence

Vulcanization of the reference rubber compound (without IL) is a two-step exothermic process. The first step occurs in a temperature range of 106–185 °C, with an enthalpy of 14.9 J g −1 (Fig. 1). This cross-linking process leads to the formation of sulfur bridges (C–S x –C) between macromolecules and cyclic combination of sulfur .

Send InquiryThe effect of dynamic vulcanization on the ... - SpringerLink

The influence of dynamic vulcanization on the amount of the sol fraction, the crosslink density, the melt flow index, and the mechanical properties of ternary (isotactic polypropylene-rubber-crumb... The effect of dynamic vulcanization on the properties of polymer-elastomer blends containing crumb rubber | SpringerLink

Send Inquiry

The effect of 42 year immersion in sea-water on natural rubber

A study has been made of the physical condition of vulcanized natural rubber retrieved after 42 yr exposure to sea-water at a water depth of 80 ft (24.3 m). Drying experiments show the maximum amount of water absorbed in the 42 yr period to have been less than 5% of the dry rubber mass.

Send InquiryCuring characteristics, mechanical properties

The influence of GTR content on the specification of the vulcanization process is presented in Fig. 1, Fig. 2, Fig. 3, Fig. 4. Figure 1 shows the effect of GTR content on the vulcanization process of obtained butyl rubber compounds. It was observed that there is an increase in minimum torque and lowered optimal time of vulcanization with the increasing GTR content.

Send InquiryELASTOSIL® E43 TRANSPARENT | Moisture Curing Silicone

After completion of the vulcanization the silicone elastomer may continuously be exposed to constantly changing climatic conditions, UV radiation and high temperature without damage. Cured ELASTOSIL® E43 usually shows good primerless adhesion to many substrates, e.g. glass, ceramics, metals, plastics and powder coatings.

Send Inquiry

VULCANIZATION OF RUBBER - NextGurukul

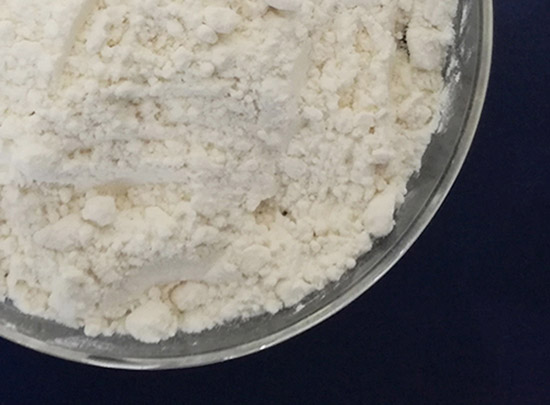

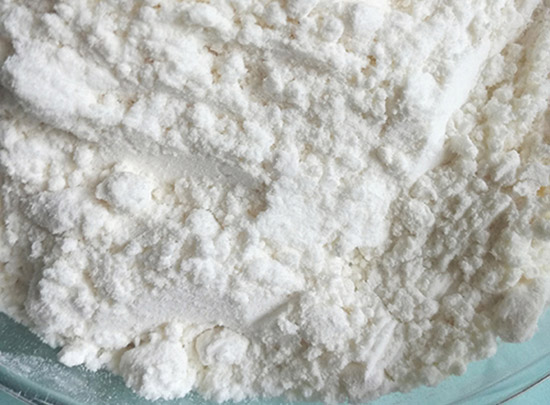

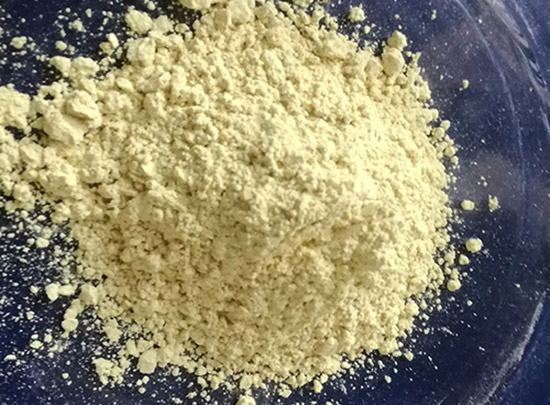

Vulcanization is a chemical process for converting rubber or related polymers into more durable materials Sulfur is used in vulcanization of rubber. Its effective and fast link in form of cross-links to rubber macromolecules.

Send Inquiry

The 4 Most Common Rubber Manufacturing Processes - The

Rollers compact the material and the overall thickness of the product is determined by the gap distance between cylinders, which can be adjusted for varying product thicknesses. Once the material passes through cooling rollers, it must be vulcanized. This process works best to produce sheets or films of rubber.

Send Inquiry

Effect of nanocrystalline cellulose on the ... - SpringerLink

Abstract. And a moderate RH content would lower the E a of vulcanization. A 10 phr substitute of CB by NCC can help to improve aging resistance in terms of mechanical properties. In a high temperature aging condition, composites with 10 phr NCC also performed the highest storage modulus ( G ′) among composites tested.

Send Inquiry

Natural rubber

Natural rubber is an elastomer and a thermoplastic. Once the rubber is vulcanized, it is a thermoset . Most rubber in everyday use is vulcanized to a point where it shares properties of both; i.e., if it is heated and cooled, it is degraded but not destroyed.

Send Inquiry

Growth and Production of Rubber

UNESCO – EOLSS SAMPLE CHAPTERS. SOILS, PLANT GROWTH AND CROP PRODUCTION - Vol.II - Growth and Production of Rubber - Willy Verheye opening up of the same cut which increased the flow of latex (wound response), the best time to tap, and the regeneration of the bark, which could then be re-tapped.

Send Inquiry

The Compounding and Vulcanization of Rubber

In the rubber industry, the problem of selecting the basic raw materials for the preparation of a specific commercial product usually is assigned to theThis background is necessary since some of the processes involve complicated chemical reactions, of which vulcanization is the most important.

Send InquiryThe Compounding and Vulcanization of Rubber

In the rubber industry, the problem of selecting the basic raw materials for the preparation of a specific commercial product usually is assigned to theThis background is necessary since some of the processes involve complicated chemical reactions, of which vulcanization is the most important.

Send Inquiry

DSC Analysis of the Induction Period in the Vulcanisation of Rubber

Vulcanisation of rubber compounds was studied by DSC under isothermal and non-isothermal conditions. The parameters of an Arrhenius-like equation describing the temperature dependence of induction period have been obtained both from isothermal and non-isothermal measurements.

Send InquiryVulcanization of Rubber | 12th Std | Chemistry | Science | CBSE Board

Our content consists of the entire 12th standard Science syllabus in a fun learning method with various sounds and animations. It is as per the current

Send Inquiry

Sulfur vulcanization

Sulfur vulcanization is a chemical process for converting natural rubber or related polymers into materials of a variety of hardness, elasticity, and mechanical durability by heating them with sulfur or other equivalent curatives or accelerators.

Send InquiryWhy is sulphur used for the vulcanization of rubber?

Actually, sulphur can only vulcanise unsaturated rubbers (polymer chain containing double bonds)Charles Good year has accidentally discovered sulphur was able to crosslink the polymer chains.Sulfur vulcanization or sulfur vulcanisation is a chemical process for converting natural rubber or

Send Inquiry

Vulcanization - an overview | ScienceDirect Topics

7.2 Definition of Vulcanization. Vulcanization is a process generally applied to rubbery or elastomeric materials.Vulcanization is a cross-linking reaction by sulfur that generates three-dimensional network structures in rubber and is the best-known process of giving rubber products greater stability.

Send Inquiry![vulcanization of rubber [substech]](/random/IMG_1808.jpg)

Vulcanization of rubber [SubsTech]

Vulcanization of rubber is a process of improvement of the rubber elasticity and strength by heating it in the presence of sulfur, which results in three-dimensional cross-linking ofWhen coagulated latex transforms into soft, plastic and sticky substance (crude rubber), which is then vulcanized (cured).

Send InquiryVulcanization of Rubber

Topics under consideration are related to rubber vulcanization and testing of cured elastomers. New ancillary chemicals used in rubber compounds[Show full abstract] kinetics of natural rubber. High vulcanization temperature resulted in high reaction rate constant. The more black carbon mixed at

Send InquiryOverview of rubber vulcanization | rubber compounding basics

Overview of rubber vulcanization. Vulcanization is the process whereby viscous and tacky raw rubber is converted into an elastic material through the incorporation of chemical crosslinks between the long molecular chains.

Send Inquiry