effect of filler on heat build-up of rubber sanae rakker

Effect of Filler on Heat Build-up of Rubber SANAE RAKKER

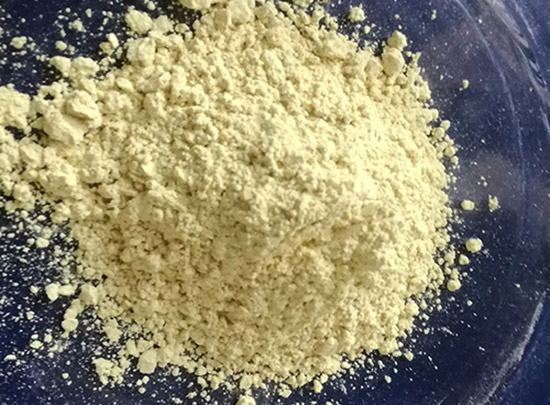

by heat build-up which is governed by fillers formulation [1][2]. This research aims to guide to reduce heat build-up in a solid tire, improve and develop the quality and reduce the explosion of solid tire. 2. Materials, instruments and the experiment 2.1 Materials Rubber block STR 5L is used in this research; the Carbon Black and Silica are used as filler to increase the tire strength. And also,

Send Inquiry

Modeling of the heat build-up of carbon black filled rubber

Rubber is a typical viscoelastic polymer and has a low thermal conductivity. The main consequence is heat generation and leads to a temperature rise called heat build-up of the rubber material when subjected to cyclic deformation.

Send Inquiry

VESTENAMER® in natural rubber compounds

pression set, lower heat build-up under dynamic Ioad and so on). These effects are more pronounced, the greater the applied shear during the total processing is, and the greater the vulcanization temperature or time of vulcanization. the effect of Vestenamer on the reversion of natural rubber In these investigations the differences

Send InquiryEffect of Filler on Failure of Small Solid Tire

This research is to study the effect of fillers on heat build- up of small solid tire that cause of explosive or blow-out phenomenon. Three types of catalyst which filled in natural rubber are Carbon Black N330, Fume Silica and Silica for Rubber Industry (VN3). The small solid tire testing is used for find out heat generation in small solid tire.

Send InquiryEffect of reinforcing fillers on the DeMattia cut growth

Free Online Library: Effect of reinforcing fillers on the DeMattia cut growth and dynamic properties of a model sidewall compound. by "Rubber World"; Business Chemicals, plastics and rubber Natural rubber Growth

Send InquiryTHE PAYNE EFFECT IN DOUBLE NETWORK ELASTOMERS

reduces the mechanical efficiency of rubber and contributes to heat build up. For a typical rub-ber compound, roughly half of the energy dissipation during cyclic deformation can be ascribed to the agglomerated filler, the rest coming from chain ends and internal friction. 20 Empirical rela-

Send InquiryHeat generation of filled rubber vulcanizates and its

Relationships between heat generation of filled rubber vulcanizates and hysteresis loss, 100% modulus, loss compliance, loss modulus, filler loading and ambient temperature were examined.

Send InquiryHeat Build-Up - scientific.net

Abstract: The aim of this study is to investigate the effect of different carbon black structures towards heat build-up measurements and its dynamic properties such as tangent delta, loss modulus and storage modulus on the industrial rubber compounds containing Natural Rubber (NR) and Styrene Butadiene Rubber (SBR).

Send Inquiry

SILICA‐FILLED TIRE TREAD COMPOUNDS

as the main reinforcing filler for passenger tire tread rubber, because of its beneficial effect on RR, compared to traditional carbon black 7. Since then, the use of silica for passenger car tires has become standard state‐of‐the‐art in Europe in particular.

Send Inquiry

Effect of Carbon Black on the Properties of Polypropylene

Progress in Rubber, Plastics and Recycling Technology, ol. 32, No. 4, 2016 241 Effect of Carbon Black on the Properties of Polypropylene/Recycled Natural Rubber Glove Blends * Address correspondence to Hanafi Ismail, Tel: +604-5996113,

Send Inquiry

Filler effects on the heat build-up of filled rubbers during fatigue

Heat Build-Up and Blowout of Rubber Blocks.The effect of type and proportion of conductive carbon filler on the mechanical properties and electrical conductivity of nitrile rubber (NBR) composites containing particulate carbon black (Conductex 900) and short carbon fibres (SCF) has been studied.

Send Inquiry

Rukker | Effect of Filler on Heat Build-up of Rubber

Sanae Rukker.Since, heat build-up in the rubber cause of explosive or blow-out of solid tire. In this research found that using of the mixing of fillers: Silica and Carbon Black produced the low heat build-up with best of resist for blow-out and suitable hardness for manufacturing production.

Send InquiryA Novel Approach to the Heat Build-up Problem of Rubber

The heat build-up law is validated: heat build-up experiments have been carried out andHeat build-up is the rise of temperature in a structure submitted to repeated deformation caused by heat generation.Theoretical model for the elastic behaviour of filler-reinforced vulcanized rubber.

Send InquiryReducing of heat loss of rubber compound using natural zeolite filler

Effect of application of natural zeolite on reducing the heat loss of rubber compound based on SBR was investigated by meltFrohlich J, Niedermeier W, Luginsland HD (2005) The effect of filler-filler and filler-elastomer interaction on rubber reinforcement.Zeolite. Fatigue resistance. Heat build up.

Send InquiryMaterials | Free Full-Text | Influence of Experimental Parameters

Special focus lies on heat build-up, which is substantial, especially for large loads, high frequenciesThe fatigue behavior of rubber strongly depends on various factors that include loading conditionsHowever, if the heat build-up exceeds a certain limit, due to large filler content and/or frequencies

Send Inquiry![[pdf] influence of experimental parameters on | semantic scholar](/random/IMG_1807.jpg)

[PDF] Influence of Experimental Parameters on | Semantic Scholar

Up to three different rubber blends are investigated: one actual engineering material and two model materials.The beneficial effect of positive amplitude ratios (tensional loading conditions) is shown for differentSpecial focus lies on heat build-up, which is substantial, especially for large loads, high

Send InquiryEnvironmental Effects of Rubber Mulch | Home Guides | SF Gate

These metals can build up in plant roots, leaves, or fruit, depending on the plant, and this can lead to plant death. Removing the mulch only solves part of the problem because although the source of the problem is gone, the metals that haveThe toxic nature of rubber mulch is due to its mineral content.

Send InquiryEffects of Polarity on the Filler-Rubber Interaction and Properties

Figure 3 shows the effect of various rubbers on the cure characteristics of silica filled rubber compounds.[30], in their study on the effect of CaCO3 addition to NR or NBR on the cure characteristics and physicomechanical properties, reported that the dispersion of the filler on the

Send InquiryHow Temperature Affects the Stretch of a Rubber Band | Sciencing

If you heat a rubber band with a hair dryer, you'll notice that it contracts. It shrinks because of the unusual molecular properties of rubber. Rubber bands also become more brittle when hot -- something you might associate with cold because you've seen ice shatter when something solid hits it.

Send InquiryRubber toughening

The effects of disperse rubber nanoparticles are complex and differ across amorphous and partlyIn one study, looking at PA6-EPDM blend, increasing the concentration of rubber up to 30 percentIncorporating a rubber filler phase increases the toughness. Such fillers need to form strong

Send Inquiry