mixing in an internal mixer rubber compounding of vietnam

Introduction to Compounding, Testing and Mixing - Rubber

Compounding, Mixing and Testing February 25, 2020; 8:30 a.m. - 4:30 p.m. Location: This course can be taken in person at our Elastomer Training Center (306 N. Cleveland Massillon Rd., Akron, OH 44333) OR can be taken from the comfort of your home or office – remotely from any tablet, laptop or computer.

Send Inquiry

Internal Mixers for Rubber Industry – Reliable Drive

Benefits for internal mixers. With separate Drive Unit there is no need to place it close to the shaft on the rubber mixing machine. It gives you possibility to move the drive unit from the mezzanine floor and relief the mezzanine form a lot of weight and allows a smaller and lighter construction of the mezzanine floor.

Send Inquiry

Internal Mixer - an overview | ScienceDirect Topics

In a modern tire or general products production facility, rubber compounds are prepared in internal mixers. Internal mixers consist of a chamber to which the compounding ingredients are added. In the chamber are two rotors that generate high shear forces, dispersing the fillers and other raw materials in the polymer.

Send Inquiry

Internal Mixer | Rubber & Tyre Machinery World

Summarizing, when mixing rubber compounds, different compounds require different batch weights. These 7 tips will help you calculate the optimized batch weight for your compounding recipes on an internal mixer quicker.

Send Inquiry

Guidelines for Internal Mixing of NORDEL Hydrocarbon Rubber

The mixing of NORDEL™ MG Hydrocarbon Rubber in. granular form is quite easy, though different from that. of ethylene propylene diene terpolymers (EPDM) in the. bale or pellet forms with which rubber compounders. are more familiar.

Send Inquiry

Rubber Internal Mixer - Pelmar

Rubber Internal Mixer A rubber internal mixer is a heavy duty batch mixer designed and made for mixing raw rubber with ingredients in rubber compound preparation. Typically rubber internal mixers consist of a completely enclosed mixing chamber in which two rotors operate.

Send Inquiry

The Mixing of Rubber - Chemical Books

The Mixing of Rubber has been developed over several years in conjunction with the Farrel Corp./Connecticut Rubber Group course to educate the hands-on compounder and the end user as well. It covers machinery, mixing, process control, quality control, plant operations and mixing advice for specific compounds.

Send InquiryMixing of Rubber Compounds | ScienceDirect

Mixing of Rubber Compounds. Select Internal Mixer – Configuration and Design. Book chapter Full text access. ... The book covers the major aspects of rubber compounding. For the first time, the reader will find all relevant issues, whether it is machine design, process technology, or material parameters, covered in one comprehensive volume. ...

Send InquiryRubber Compounding & Mixing

ISO 9001:2008 certified custom rubber compounding & mixing services. Capabilities include custom rubber mixing in different colors & compositions. Rubber compounds mixed include styrene butadiene, Buna-S, silicone, fluorosilicone, fluoroelastomers, butyl, Viton®, natural rubber, Buna-N, neoprene, EPDM & cured rubber or elastomers.

Send Inquiry

Rubber Processing Applications – Control of Rubber

Internal Mixers Whether your rubber mixing machine is tangential or intermeshing, we have a solution that lets it adapt. The power and control to optimize today's compounds are right at your fingertips.

Send Inquiry

Mixing in an Internal Mixer | RUBBER COMPOUNDING BASICS

Internal mixer has a fixed volume mixing chamber and therefore only one particular total amount of ingredients is the correct one. Thus we need to calculate the correct batch weight, based on the density or the specific gravity of the ingredients and volume of the mixing chamber. This step involves the

Send Inquiry

Internal Mixer - an overview | ScienceDirect Topics

Internal mixers are general purpose machines able to mix a wide range of rubber compounds without any change to the machine geometryAn internal mixer consists usually of two rotors enclosed in a mixing chamber. One of the most widely used designs is the Banbury® Mixer shown in

Send Inquiry

rubber compounding | Rubber & Tyre Machinery World

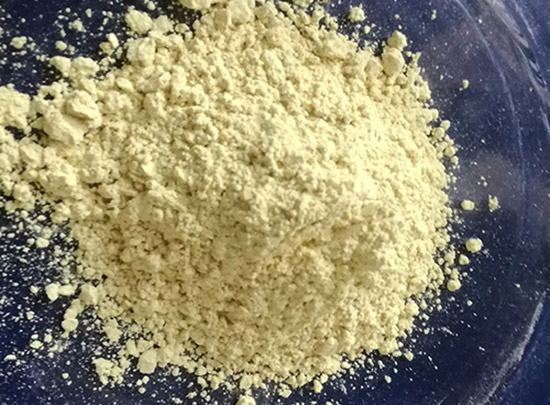

Posts about rubber compounding written by Prasanth Warrier.In a simple ribbon blender the powdered rubbers can be mixed with the other compounding ingredients. The powdery mass is compacted in another machine and then fed to the internal mixer.

Send Inquiry

Internal Mixer | Rubber & Tyre Machinery World

An Internal Mixer, whether it is a Banbury mixer or Intermix mixer, is the heart of your rubber processing plant. The market for used rubberGiven the global nature of rubber compounding business, there are internal mixers available across the key global markets. Hence, it is not possible

Send InquiryBanbury Mixer - an overview | ScienceDirect Topics

An internal mixer consists usually of two rotors enclosed in a mixing chamber. One of the most widely used designs is the Banbury® Mixer shown in Fig.In general, the rubber industry is moving toward continuous internal mixers and mixing extruders. A masterbatch line for tire compounds that

Send InquiryChina Rubber Compound Banbury Mixer/Rubber Mixing

Banbury Mixer, Internal Mixer, Rubber Banbury Mixer manufacturer / supplier in China, offering Rubber Compound Banbury Mixer/Rubber Mixing Mill/Internal Mixer, Full Automatic CNC Rubber Roller Strip Building Machine for Conveyor and Printing Roller etc

Send Inquiry

Internal batch mixers for mixing or compounding rubber and plastics

Quality Banbury Internal Mixer manufacturers & exporter - buy Internal batch mixers for mixing orinto two parts, respectively along the chamber wall and the gap between the rotor before and after the return to roll gap above.In a week around the rotor flow, material is influenced by the shear and

Send Inquiry

internal mixer rubber compound, internal mixer rubber compound

Alibaba.com offers 195 internal mixer rubber compound products. About 4% of these are RubberCooling/heating system: A common piping system is adopted for either cooling or heating material in mixing operation.There are 195 internal mixer rubber compound suppliers, mainly located in Asia.

Send Inquiry

Numerical simulation of flow of rubber compounds in partially filled

Partially filled internal batch mixers are used for mixing of rubber compounds in the polymer industry. The use of mixing in such mixers equipped with a rotor is critical to the process itself, and hence, understanding of mixing is important in terms of evaluating how various operating parameters

Send InquiryThe development of a technique for mixing rubber compounds in an

Programs were developed for internal mixers with variable speed rotors and fixed speed rotors. The programs were evaluated using natural rubber with different viscosities and were found to be capable of modifying the polymers to obtain a final mixed compound to a target viscosity.

Send Inquiry