hot sales sulphur and peroxide vulcanisation of rubber in singapore

Mechanism of Rubber Vulcanization with Sulfur - Industrial

If you no longer have access with this institution, try logging in with your ACS ID. Type part of your institution name for a list of matches. If your institution is not listed, please contact your librarian. No institution has been found Unable to find the university or organization name. Please ...

Send Inquiry

Main Use Of Vulcanizing Agent - News - Rubber Chem

As a variety of rubber peroxide vulcanizing agent, especially in the butyl clear gum, EPDM and rubber and the peroxide vulcanization process in the body, can play a low compression deformation, fast vulcanization and heat-resistant air aging of the compound.

Send InquirySulfur For Vulcanization, Sulfur For Vulcanization

Alibaba.com offers 570 sulfur for vulcanization products. About 1% of these are elementary substances, 1% are electronics chemicals, and 1% are other inorganic chemicals. A wide variety of sulfur for vulcanization options are available to you, such as electronics chemicals, coating auxiliary agents, and rubber auxiliary agents.

Send InquiryThe Role Of Vulcanizing Agent

The common industrial Sulphur additive TMTD and tetd can produce carcinogenic N-nitro-dimethyl amine during vulcanization. At present, the Platinum curing agent (low vulcanization temperature, fast curing speed) is used as vulcanizing agent of silicone rubber in some special products.

Send InquiryRubber vulcanization, a technological breakthrough

In this post we want to mention that although a fact is not widely known it does not cease to be a technological breakthrough in the industry, marking a turning point, as was the discovery of rubber vulcanization. It was the North American Charles Goodyear who, in 1839, accidently spilled a container of sulfur and rubber onto a hot stove.

Send InquiryAlternative Curing Process for EPDM Rubber - LANXESS

Depending on the particular resol curing system and rubber under investigation, the cure rate is strongly increased. This means a reduction of scorch and vulcanisation times up to 75 per cent. Furthermore, the final degree of crosslinking is clearly enhanced – almost up to the double value.

Send InquiryThe common accelerators in producing rubber

So far since the invention of the rubber vulcanization, sulfur is always natural rubber and most of the diolefins general synthetic rubber main sulfurization agent, it was the emergence of many new sulfurization agent to improve the performance of the rubber products plays a significant all with, but the price is generally more expensive, so ...

Send InquiryRUBBER CHEMISTRY - Läroverket i Småland AB

between rubber macromolecules (such as sulphur, peroxides, metal oxides, resins, quinones and others), which can react with appropriate functional rubber groups in the process of vulcanization to create transverse bonds between them. The cross-linking can be induced also by radiation, however its energy must be sufficient to

Send InquiryVulcanization & Accelerators

Vulcanization of rubbers by sulfur alone is an extremely slow and inefficient process. The chemical reaction between sulfur and the Rubber Hydrocarbon occurs mainly aC (doublet the C = bonds ) and each crosslink requires 40 to 55 sulphur atoms (in the absence of accelerator). The process takes around 6 hours at 140°C

Send Inquiry

A Beginner's Guide to Rubber: Rubber Vulcanization

Continuous vulcanization is a single-line operation, the shaped uncured product is transferred along a curing medium such as liquid, hot air, steam, microwaves and infrared, and high-energy radiation, the rubber is then cut to produce extruded goods, coated wiring, conveyor belts and flooring.

Send Inquiry

Sulphur and peroxide vulcanisation of rubber compounds – overview

Vulcanisation is a process of transforming a plastic rubber compound into a highly elastic product by forming a three-dimensional cross-linked network structure in the rubber matrix. Many systems have been developed to vulcanise rubber compounds, among which sulphur and peroxide curing

Send Inquiry

Why is sulphur used for the vulcanization of rubber?

Actually, sulphur can only vulcanise unsaturated rubbers (polymer chain containing double bonds) like Natural rubber, StyreneIf you ask me why only sulphur and not phosphorus or other inorganic compounds can be used for vulcanisation, then this is one question really nobody knows the answer.

Send Inquiry

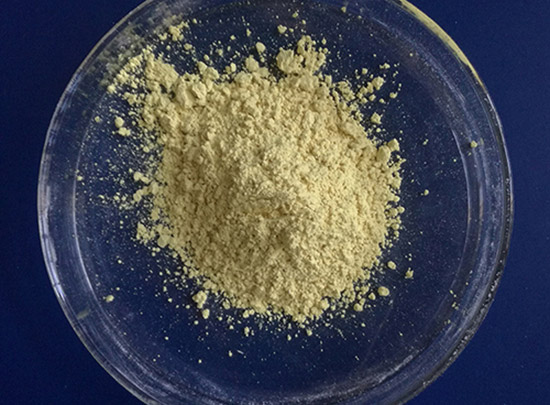

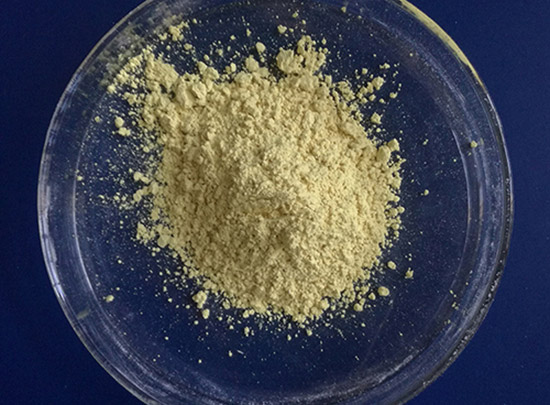

Sulfur vulcanization

Sulfur vulcanization is a chemical process for converting natural rubber or related polymers into materials of a variety of hardness, elasticity, and mechanical durability by heating them with sulfur or other equivalent curatives or accelerators.

Send Inquiry

Vulcanization - an overview | ScienceDirect Topics

Vulcanization is a chemical process in which the rubber is heated with sulphur, accelerator and activator at 140–160°C. The process involves the formation of cross-links between long7.2 Definition of Vulcanization. Vulcanization is a process generally applied to rubbery or elastomeric materials.

Send Inquiry

Sulphur and peroxide vulcanisation of rubber compounds – overview

Sulphur and peroxide vulcanisation of rubber compounds – overview. Ján Kruželák, Richard Sýkora, Ivan Hudec. Chemical Papers, January 2016, De Gruyter. DOI: 10.1515/chempap-2016-0093.

Send InquiryAn Accelerator Free Peroxide Vulcanization Technique

Peroxide vulcanization of latex was a simple process ,here peroxide with. activator is used for vulcanizing dry rubber instead of sulphur Hydro-peroxide vulcanized lattices can produce films with physical properties similar to those of sulphur vulcanized latex films The basic mechanism of

Send InquirySulphur Vulcanisation of Styrene

Sulphur Vulcanisation of Styrene Butadiene Rubber using New Binary Accelerator Systems. A.Unlike natural rubber, in the vulcanisation of styrene butadiene rubber, a copolymer, the crosslink formation is relatively slower and therefore requires higher amounts of accelerator and lower levels of

Send Inquiry

Why sulfur is used in vulcanisation of rubber - Answers

vulcanisation- when sulfur atoms form cross-links between rubber moleculesHe accidentally discovered the process of vulcanisation of rubber when he dropped some rubber mixed with sulfur on a hot stove.Sulphur (Sulfur) is added to rubber in the process known as vulcanization.

Send Inquiry

Compounding and Vulcanization of Rubber | Engineering360

Peroxides function as plasticizers, vulcanizing agents, and curatives.Vulcanization of Rubber. Non cross-linked rubber products, such as natural rubber obtained from latex, are softThe addition of sulphur to hot rubber causes structural changes, which improves the physical properties of rubber.

Send InquiryOverview of rubber vulcanization | rubber compounding basics

Vulcanization is the process whereby viscous and tacky raw rubber is converted into an elasticCrosslink Formation in Sulfur Vulcanization. Sulphur, accelerator, zinc oxide & stearic acidOnly crosslink structures which form bridges between rubber chains are useful as stress-bearing members

Send Inquiry