cn102718728b refining process of rubber vulcanization

CN102718728B - Refining process of rubber vulcanization

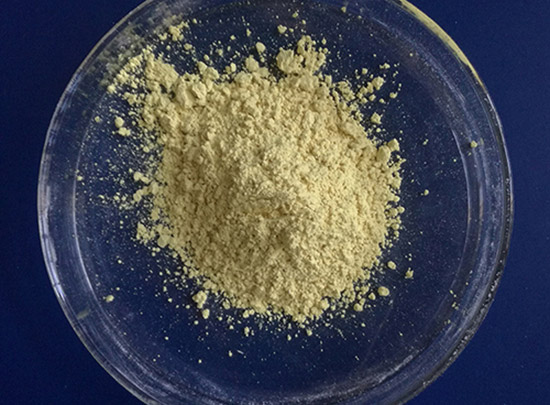

The present invention discloses a new purification process of rubber vulcanization accelerator MBT the agent. The method describes the recovery process to promote recrystallization and purification agents MBT solvent.

Send InquiryThe Manufacturing Process of Rubber | Sciencing

The rubber production process begins with natural or synthetic rubber. Natural rubber comes from latex. Synthetic rubber derives from molecular polymers. Whether natural or synthetic, rubber continues through four steps: compounding, mixing, molding and casting, and, finally, vulcanization.

Send Inquiry

Vulcanization | rubber manufacturing | Britannica

Vulcanization, chemical process by which the physical properties of natural or synthetic rubber are improved; finished rubber has higher tensile strength and resistance to swelling and abrasion, and is elastic over a greater range of temperatures. In its simplest form, vulcanization is brought about by heating rubber with sulfur.

Send Inquiry

Our Rubber Devulcanizing Solution

Devulcanized Rubber Production Conventional vs New Devulcanizing Systems The conventional method of delinking is done in a devulcanizer where high pressure of up to 4 MPa and temperature of up to 300°C is required, and water is used as a medium. This process has its inherent safety risk due to the high pressure employed.

Send Inquiry

BR102016022898A2 - Dregs treatment process, treated dregs

dregs treatment process, treated dregs, their use, rubber vulcanization process, and vulcanized rubber. The invention relates to a method of treating dregs for its application as a vulcanization activator of rubbers, terminating this waste generated in the pulp industry and providing vulcanized rubbers with similar or improved properties than those already known.

Send InquiryRotocure Vulcanizing Press | Rubber ... - rubber process

The Shun Cheong rotocure vulcanizing press is one of our high qualtiy vulcanization machines used in the production of rubber products.

Send Inquiry

RUBBER CHEMISTRY - Läroverket i Småland AB

Rubbers are used most often in the form of vulcanizates - a vulcanized rubber. They can be brought to this form by vulcanization. This process is based on creation of chemical and physical transverse bonds between rubber macromolecules resulting in a spatial vulcanizate mesh, giving unique properties to the material. Various

Send Inquiry

Use of by-product Sulfur from Petroleum Refinery as

Sulfur is typically required for rubber vulcanization in order to achieve enhanced mechanical strength and elastic behavior. Basically, the sulfur used in rubber industry originates from natural ...

Send InquiryThe Manufacturing Process of Rubber - Seacon Corporation

Synthetic rubber production begins with the refining of oil, coal or other hydrocarbons. During the refining process, naphtha is produced. The naphtha is collected and can then be combined with natural gas to produce monomers such as styrene and isoprene, which are necessary for the production of synthetic rubber.

Send Inquiry

Processing and Profiting from Rubber | HowStuffWorks

Processing natural rubber consists of the following steps: Companies begin by obtaining the latex fluid, which means tapping the sap from the rubber trees, filtering the latex and then packaging it in drums for export or processing. They make smoked sheets of latex rubber.

Send InquirySulfur vulcanization

Sulfur vulcanization is a chemical process for converting natural rubber or related polymers into materials of a variety of hardness, elasticity, and mechanical durability by heating them with sulfur or other equivalent curatives or accelerators.

Send InquiryVulcanization

Vulcanization (British: vulcanisation) is a chemical process, invented by Charles Goodyear, used to harden rubber. Vulcanization traditionally referred to the treatment of natural rubber with sulfur and this remains the most common example

Send InquiryVulcanization - an overview | ScienceDirect Topics

Vulcanization is a process generally applied to rubbery or elastomeric materials.Vulcanization, named after Vulcan, the Roman God of Fire, describes the process by which physically soft, compounded rubber materials are converted into high-quality engineering products.

Send InquiryVulcanization process of rubber - nurchem - Medium

Rubber vulcanization process can be divided into four curing stages: scorch stage, pre-sulfur phase, sulfur phase, over-sulfur phase.tage, the physical and mechanical properties of vulcanized rubber are not at the same time reached the highest value, but were close to or close to the best value, the

Send Inquiry

Vulcanization of Rubber | 12th Std | Chemistry | Science | CBSE Board

Vulcanisation of Rubber | Carbon Compound - Продолжительность: 6:19 myhometuition 8 549 просмотров.Rubber Molded Products Manufacturing Process - Industrial Animation - Продолжительность: 4:41 Virtual Element Studios 67 010 просмотров.

Send Inquiry

How to Vulcanize Rubber. Rubber Vulcanization Process.

Natural rubber processing - Продолжительность: 7:38 Shaiju Narayanan Recommended for you.Melting Aluminum Cans At Home - Easy DIY Recycling Process - Продолжительность: 11:21 ArtByAdrock Recommended for you.

Send InquiryVulcanization - Rubber as a natural product - JRank Articles

Vulcanization is the process by which rubber molecules (polymers or macromolecules made of repeating units or monomers called isoprene) are cross-linked with each other by heating the liquid rubber with sulfur. Cross-linking increases the elasticity and the strength of rubber by about ten-fold

Send Inquiry

Vulcanization | rubber manufacturing | Britannica

Vulcanization, chemical process by which the physical properties of natural or synthetic rubber are improved; finished rubber has higher tensile strength and resistance to swelling and abrasion, and is elastic over a greater range of temperatures. In its simplest form, vulcanization is brought.

Send InquiryWhat is vulcanised rubber?

Vulcanization or vulcanisation is a chemical process for converting natural rubber or related polymers into more durable materials via the addition of sulfur or other equivalent curatives orTalking of vulcanizing rubber is incomplete without delving into some history. You will find it quite interesting.

Send Inquiry

The Manufacturing Process of Rubber | Sciencing | Vulcanization

The rubber production process begins with natural or synthetic rubber. Natural rubber comes from latex. Synthetic rubber derives from molecular polymers. Whether natural or synthetic, rubber continues through four steps: compounding, mixing, molding and casting, and, finally, vulcanization.

Send Inquiry