rubber vulcanization at guatemala

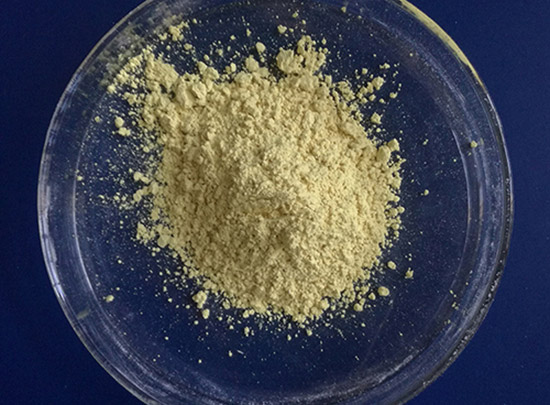

Sulfur vulcanization

This process is called inverse vulcanization and produces polymers where sulfur is the main component. History. The curing of rubber has been carried out since prehistoric times. The name of the first major civilization in Guatemala and Mexico, the Olmec, means 'rubber people' in the Aztec language.

Send Inquiry

Aztec, Maya Were Rubber-Making Masters?

Ancient civilizations in much of Mexico and Central America were making different grades of rubber 3,000 years before ... court in Guatemala that's been ... called vulcanization, which cooks ...

Send Inquiry

Devulcanization - VIRGIN RUBBER ALTERNATIVE

The license to use NGR ® technology for de-vulcanization of waste rubber and production of NGR ® products. Turn-key construction of the production plant for the Licensees with all necessary equipment. Necessary quantity of NGD® de-vulcanizer for production of NGR ® products.

Send InquiryFONMAR S.A., Machinery for Vulcanization

FONMAR S.A. is a global leader in the manufacture of vulcanizers for Rubber, PVC & PU Conveyor Belts, as well as tire repair machines by means of vulcanization. FONMAR S.A. also supplies vulcanizers and other kind of tools to manufacturers of conveyor belts, dealers and service companies.

Send InquiryFrom dentures to death: Where the rubber met the road for

From dentures to death: Where the rubber met the road for one patent troll. Image June 1, 2017 June 2, ... One of the most revolutionary items made with vulcanized rubber was the base for dentures. Once dentists found this material and started using it, it ushered in what has been called “the era of false teeth for the masses” beginning in ...

Send InquiryVulcanization - an overview | ScienceDirect Topics

Vulcanization. Vulcanization is a chemical process in which the rubber is heated with sulphur, accelerator and activator at 140–160°C. The process involves the formation of cross-links between long rubber molecules so as to achieve improved elasticity, resilience, tensile strength, viscosity, hardness and weather resistance.

Send InquirySulfur Vulcanization

Vulcanization is a chemical process that converts natural rubber and other polydiene elastomers into cross-linked polymers. The most common vulcanization agent is sulfur. It forms bridges between individual polymer molecules when heated with rubber. Often a catalyst and initiator is added to accelerate the vulcanization process.

Send Inquiry

A Beginner's Guide to Rubber: Rubber Vulcanization

A Beginner's Guide to Rubber: Rubber Vulcanization . There are many ways to form rubber parts, part 3 of this guide will discuss the remaining more popular processes used in the industry today. As mentioned earlier, the process for turning rubber compounds into usable finished products is vulcanization. There are various types of vulcanization ...

Send Inquiry

Vulcanization | rubber manufacturing | Britannica

Vulcanization, chemical process by which the physical properties of natural or synthetic rubber are improved; finished rubber has higher tensile strength and resistance to swelling and abrasion, and is elastic over a greater range of temperatures. In its simplest form, vulcanization is brought about by heating rubber with sulfur.

Send Inquiry

Vulcanization

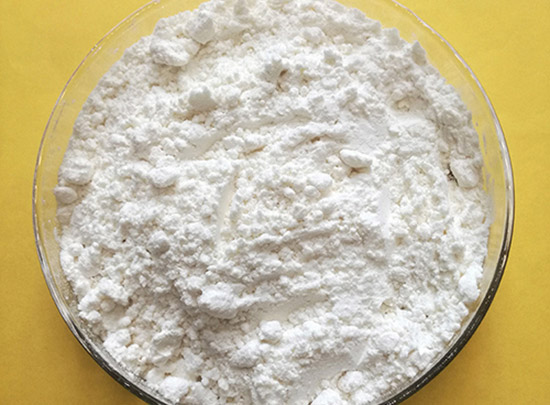

Vulcanization (British: vulcanisation) is a chemical process, invented by Charles Goodyear, used to harden rubber. Vulcanization traditionally referred to the treatment of natural rubber with sulfur and this remains the most common example, however the term has also grown to include the hardening of other (synthetic) rubbers via various means. Examples include silicone rubber via room ...

Send Inquiry

Sulfur vulcanization

This process is called inverse vulcanization and produces polymers where sulfur is the main component. History. The curing of rubber has been carried out since prehistoric times. The name of the first major civilization in Guatemala and Mexico, the Olmec, means 'rubber people' in the Aztec language.

Send Inquiry

Aztec, Maya Were Rubber-Making Masters?

Ancient civilizations in much of Mexico and Central America were making different grades of rubber 3,000 years before court in Guatemala that's been called vulcanization, which cooks

Send InquiryDevulcanization - VIRGIN RUBBER ALTERNATIVE

The license to use NGR ® technology for de-vulcanization of waste rubber and production of NGR ® products. Turn-key construction of the production plant for the Licensees with all necessary equipment. Necessary quantity of NGD® de-vulcanizer for production of NGR ® products.

Send Inquiry

FONMAR S.A., Machinery for Vulcanization

FONMAR S.A. is a global leader in the manufacture of vulcanizers for Rubber, PVC & PU Conveyor Belts, as well as tire repair machines by means of vulcanization. FONMAR S.A. also supplies vulcanizers and other kind of tools to manufacturers of conveyor belts, dealers and service companies.

Send InquiryVulcanization & Accelerators

Vulcanization & Accelerators Vulcanization is a cross linking process in which individual molecules of rubber (polymer) are converted into a three dimensional network of interconnected (polymer) chains through chemical cross links(of sulfur). The vulcanization process was discovered in 1839 and the individuals responsible for this discovery were

Send InquiryVulcanization | rubber manufacturing | Britannica

Vulcanization, chemical process by which the physical properties of natural or synthetic rubber are improved; finished rubber has higher tensile strength and resistance to swelling and abrasion, and is elastic over a greater range of temperatures. In its simplest form, vulcanization is brought about by heating rubber with sulfur.

Send Inquiry5 Ways Rubber Has Changed the World | Eco Green Equipment

The discovery of vulcanization to make rubber hardy enough for significant wear helped make the leap to using rubber for tires. Rubber tires came to bicycles first, and then were adapted for automobiles. The modern auto industries simply would not be what they are today if it weren’t for rubber tires.

Send Inquiry

Buffers & Bumpers | United States of America

The vulcanization guarantees the highest cohesiveness between rubber and steel. Rubber to metal rails - metal parts primed, vulcanized to one or two sides Rubber to metal elements - metal parts yellow aodized, vulcanized to one or two sides

Send Inquiry