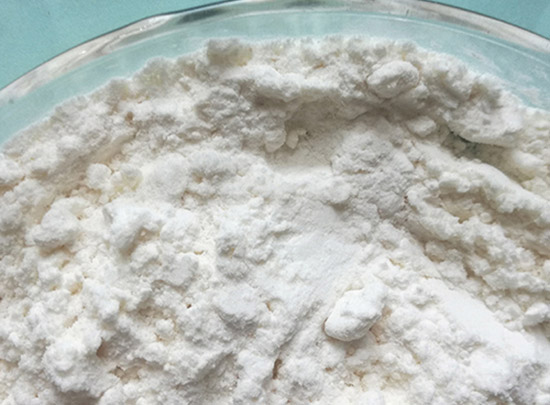

rubber processing chemical vulcanization accelerator

Vulcanization Accelerators

Accelerators for Sulfur Vulcanization of Rubbers. Vulcanization of rubber by sulfur alone is an extremely slow process and can take several hours at elevated temperature (140 C or more). This is problematic becasue long exposure to temperature and oxygen leads to oxidative degradation which, in turn, results in poor mechanical properties.

Send InquiryVulcanization & Accelerators

Vulcanization of rubbers by sulfur alone is an extremely slow and inefficient process. The chemical reaction between sulfur and the Rubber Hydrocarbon occurs mainly aC (doublet the C = bonds ) and each crosslink requires 40 to 55 sulphur atoms (in the absence of accelerator). The process takes around 6 hours at 140°C

Send Inquiry

Accelerator | rubber manufacturing | Britannica

Accelerator. Accelerator, in the rubber industry, any of numerous chemical substances that cause vulcanization ( q.v.) of rubber to occur more rapidly or at lower temperatures. Many classes of compounds act as accelerators, the most important being organic materials containing sulfur and nitrogen, especially derivatives...

Send InquiryAccelerator NOBS - Rubber Chem

This is a delayed active vulcanization accelerator, short curing time, high anti-scorching quality and safe processing. Physical and antioxidant quality of vulcanized rubber are superior. Mainly used for the manufacturing of tire, tube, shoes, rubber tape, conveyor belt, etc.

Send InquiryVulcanization - an overview | ScienceDirect Topics

Vulcanization is a chemical process in which the rubber is heated with sulphur, accelerator and activator at 140–160°C. The process involves the formation of cross-links between long rubber molecules so as to achieve improved elasticity, resilience, tensile strength, viscosity, hardness and weather resistance.

Send InquiryRubber Processing Chemical - Vulcanization Accelerator

Manufacturer of Rubber Processing Chemical - Vulcanization Accelerator, Anti Reversion Agent, Post Vulcanization Stabilizer and Reinforcing Agent offered by Spechem (india) Pvt. Ltd., Chennai, Tamil Nadu.

Send Inquiry

SULFUR VULCANIZATION OF NATURAL RUBBER FOR BENZOTHIAZOLE

The chemistry of accelerated sulfur vulcanization is reviewed and a fundamental kinetic model for the vulcaniza-tion process is developed. The vulcanization of natural rubber by the benzothiazolesulfenamide class of accelerators is studied, where 2-(morpholinothio) benzothiazole (MBS) has been chosen as the representative accelerator. The reaction

Send Inquiryacceleratorsand acceleratorsystems

An accelerator is defined as the chemical added into a rubber compound to increase the speed of vulcanization and to permit vulcanization to proceed at lower temperature and with greater efficiency. Over 150 different chemicals belonging to different classes of composition are known to function as acceler-

Send InquiryVulcanization | rubber manufacturing | Britannica

Written By: Vulcanization, chemical process by which the physical properties of natural or synthetic rubber are improved; finished rubber has higher tensile strength and resistance to swelling and abrasion, and is elastic over a greater range of temperatures. In its simplest form, vulcanization is brought about by heating rubber with sulfur.

Send InquiryVulcanization

Vulcanization (British: vulcanisation) is a chemical process, invented by Charles Goodyear, used to harden rubber. Vulcanization traditionally referred to the treatment of natural rubber with sulfur and this remains the most common example, however the term has also grown to include the hardening of other (synthetic) rubbers via various means. Examples include silicone rubber via room temperature vulcanizing and chloroprene rubber (neoprene) using metal oxides.

Send Inquiry

Vulcanization & Accelerators

Vulcanization of rubbers by sulfur alone is an extremely slow and inefficient process. The chemical reaction between sulfur and the Rubber Hydrocarbon occurs mainly aC (doublet the C = bonds ) and each crosslink requires 40 to 55 sulphur atoms (in the absence of accelerator). The process takes around 6 hours at 140°C

Send Inquiry

Vulcanization Accelerators

Accelerators for Sulfur Vulcanization of Rubbers. Vulcanization of rubber by sulfur alone is an extremely slow process and can take several hours at elevated temperature (140 C or more). This is problematic becasue long exposure to temperature and oxygen leads to oxidative degradation which, in turn, results in poor mechanical properties.

Send Inquiry

Vulcanization - an overview | ScienceDirect Topics

Vulcanization is a chemical process in which the rubber is heated with sulphur, accelerator and activator at 140–160°C. The process involves the formation of cross-links between long rubber molecules so as to achieve improved elasticity, resilience, tensile strength, viscosity, hardness and weather resistance.

Send InquiryAccelerator NOBS - Rubber Chem

This is a delayed active vulcanization accelerator, short curing time, high anti-scorching quality and safe processing. Physical and antioxidant quality of vulcanized rubber are superior. Mainly used for the manufacturing of tire, tube, shoes, rubber tape, conveyor belt, etc.

Send Inquiry

Accelerant

Rubber vulcanization. It typically consists of natural rubber with a very high sulfur level (up to 8 phr), to get a relatively stiff rubber, with sulfur promoting the adhesion with the steel cord. The basis of the tire is formed by the carcass, normally a mixture of NR ( natural rubber ), SBR and BR.

Send InquiryVulcanization

Vulcanization (British: vulcanisation) is a chemical process, invented by Charles Goodyear, used to harden rubber. Vulcanization traditionally referred to the treatment of natural rubber with sulfur and this remains the most common example, however the term has also grown to include the hardening of other (synthetic) rubbers via various means. Examples include silicone rubber via room temperature vulcanizing and chloroprene rubber (neoprene) using metal oxides.

Send InquiryVulcanization | rubber manufacturing | Britannica

Written By: Vulcanization, chemical process by which the physical properties of natural or synthetic rubber are improved; finished rubber has higher tensile strength and resistance to swelling and abrasion, and is elastic over a greater range of temperatures. In its simplest form, vulcanization is brought about by heating rubber with sulfur.

Send Inquiry

Accelerator | rubber manufacturing | Britannica

Accelerator Accelerator, in the rubber industry, any of numerous chemical substances that cause vulcanization (q.v.) of rubber to occur more rapidly or at lower temperatures. Many classes of compounds act as accelerators, the most important being organic materials containing sulfur and nitrogen, especially derivatives of benzothiazole.

Send Inquiry