radiation vulcanization of natural rubber latex using

Radiation vulcanization of natural rubber latex using

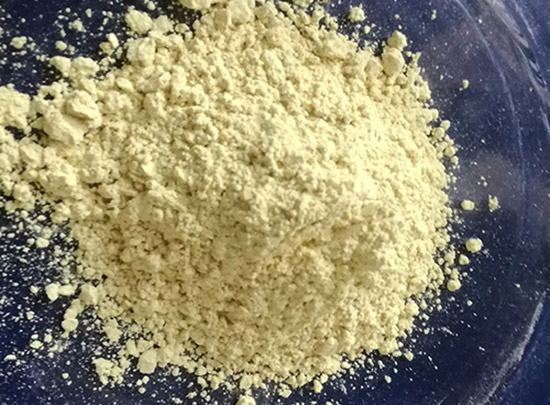

Phenoxy ethyl acrylate can be used for radiation vulcanization of natural rubber latex since it imparts more or less similar physical properties compared to that of n-BA. When compared to PEA, the tensile properties of RVNRL, prepared by using TMPTMA was comparatively lower.

Send InquiryRadiation vulcanization of natural rubber latex using

At present, there are three popular vulcanization processes being used in natural rubber latex industries, which are sulfur, radiation and peroxide vulcanization.

Send InquiryRadiation vulcanization of natural rubber latex using a

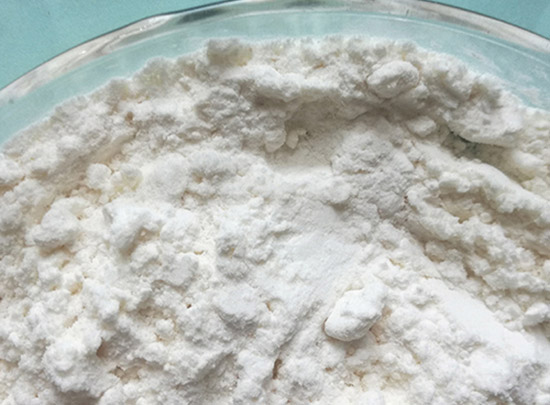

EA, MA and MMA in radiation vulcanization of natural rubber latex has been studied. It was found that n-BA in a small quantity, about 2 phi (per hundred of rued), was the best monofunctional amonomer as a sensitizer in radiation vukaniation of natural rubber latex.

Send InquiryRadiation vulcanization of natural rubber latex using a

It was found that n-BA in a small quantity, about 2 phr (per hundred of rubber), was the best monofunctional acrylic monomer as a sensitizer in radiation vulcanization of natural rubber latex. A combination of n-BA with CCl 4 (1/1 phr), showed a better result as promising sensitizer mixture.

Send InquiryRadiation vulcanization of natural rubber latex

Natural rubber latex was irradiated with γ-rays from Co-60 in the presence of polyfunctional monomers to accelerate crosslinking of rubber molecules. Hydrophobic monomers were more effective in accelerating the vulcanization than were hydrophilic monomers. This was ascribed to high solubility of hydrophobic monomers in rubber particles.

Send InquiryInvestigation of Radiation Vulcanization of Natural Rubber

Radiations vulcanization of natural rubber latex (RVNRL) has been developed extensively through various research and development programme. This holds important benefits for rubber industries in Southeast Asia and the Pacific region.

Send Inquiry

Radiation processing of natural rubber latex

The technology is called radiation vulcaniza-tion of natural rubber latex, or RVNRL. It uses high-energy gamma radiation (it also can use electron beams) to initiate vulcanization, a process that chemically bonds molecules to produce rubber elasticity and strength. As with other radiation industrial processes, products are not radioactive.

Send Inquiry

RADIATION VULCANIZATION OF NATURAL RUBBER LATEX SENSITIZED

butadiene, were selected as sensitizers for the radiation vulcanization of natural rubber latex instead of acrylates. These gases accelerate the crosslinking rates of the cure process and lower the radiation dose required to achieve vulcanization of natural rubber latex and improve the mechanical properties to reduce the tackiness of rubber goods.

Send InquiryInvestigation of Radiation Vulcanization of Natural Rubber

radiation vulcanized natural rubber latex films to see whether similar improvement can also be obtained for the radiation vulcanization process. Natural rubber latex (NRL) is a dispersion of natural rubber particles in water. It comes from Hevea Brasiliensis plantation [5].The properties of natural rubber can be

Send InquiryRadiation vulcanization of natural rubber latex using

Radiation vulcanization of natural rubber latex using TMPTMA and PEA Results indicated that the PEA is a more effective accelerator for RVNRL since it imparts approximately equivalent physical properties compared to that of n -butyl acrylate ( n -BA), the most widely used accelerator.

Send InquiryRadiation vulcanization of natural rubber latex using

Phenoxy ethyl acrylate can be used for radiation vulcanization of natural rubber latex since it imparts more or less similar physical properties compared to that of n-BA. When compared to PEA, the tensile properties of RVNRL, prepared by using TMPTMA was comparatively lower.

Send InquiryRadiation vulcanization of natural rubber latex using

At present, there are three popular vulcanization processes being used in natural rubber latex industries, which are sulfur, radiation and peroxide vulcanization.

Send InquiryRadiation vulcanization of natural rubber latex using a

EA, MA and MMA in radiation vulcanization of natural rubber latex has been studied. It was found that n-BA in a small quantity, about 2 phi (per hundred of rued), was the best monofunctional amonomer as a sensitizer in radiation vukaniation of natural rubber latex.

Send Inquiry

Radiation vulcanization of natural rubber latex using a

It was found that n-BA in a small quantity, about 2 phr (per hundred of rubber), was the best monofunctional acrylic monomer as a sensitizer in radiation vulcanization of natural rubber latex. A combination of n-BA with CCl <SUB>4</SUB> (1/1 phr), showed a better result as promising sensitizer mixture.

Send InquiryRadiation vulcanization of natural rubber latex

Natural rubber latex was irradiated with γ-rays from Co-60 in the presence of polyfunctional monomers to accelerate crosslinking of rubber molecules. Hydrophobic monomers were more effective in accelerating the vulcanization than were hydrophilic monomers. This was ascribed to high solubility of hydrophobic monomers in rubber particles.

Send Inquiry

Investigation of Radiation Vulcanization of Natural Rubber

Radiations vulcanization of natural rubber latex (RVNRL) has been developed extensively through various research and development programme. This holds important benefits for rubber industries in Southeast Asia and the Pacific region.

Send Inquiry

Radiation processing of natural rubber latex

The technology is called radiation vulcaniza-tion of natural rubber latex, or RVNRL. It uses high-energy gamma radiation (it also can use electron beams) to initiate vulcanization, a process that chemically bonds molecules to produce rubber elasticity and strength. As with other radiation industrial processes, products are not radioactive.

Send Inquiry

RADIATION VULCANIZATION OF NATURAL RUBBER LATEX SENSITIZED

butadiene, were selected as sensitizers for the radiation vulcanization of natural rubber latex instead of acrylates. These gases accelerate the crosslinking rates of the cure process and lower the radiation dose required to achieve vulcanization of natural rubber latex and improve the mechanical properties to reduce the tackiness of rubber goods.

Send Inquiry