polymer additives primary and secondary antioxidants

Polymer Additives - Primary and Secondary Antioxidants

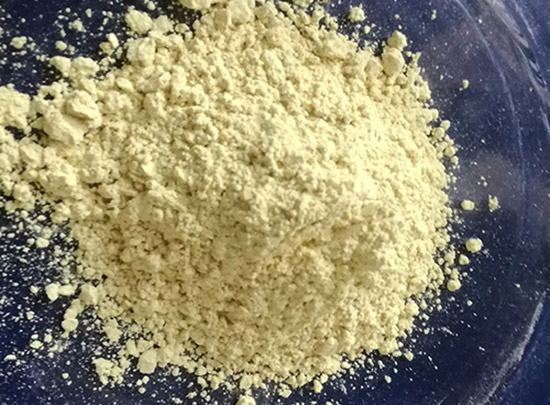

Polymer Additives - Primary and Secondary Antioxidants. Practically all polymer materials undergo oxidative degradation reactions occurring at one or all of the manufacturing, processing and end-use stages.

Send InquirySecondary Antioxidant - an overview | ScienceDirect Topics

Phosphites, and in particular organophosphorus compounds, are secondary antioxidants that decompose peroxides and hydroperoxides into stable, nonradical products, according to Scheme 4.4.They are extremely effective stabilizers during processing and are normally used in combination with a primary antioxidant. Trivalent phosphorus compounds are excellent hydroperoxide decomposers.

Send Inquiry

Primary Antioxidants: Antioxidants Selection for Adhesives

Phenolic stabilizers are primary antioxidants that act as hydrogen donors. They react with peroxy radicals to form hydroperoxides and prevent the abstraction of hydrogen from the polymer backbone. Often used in combination with secondary antioxidants, phenolic stabilizers are offered in an extensive range of molecular weights, product forms, and functionalities.

Send Inquiry

BASF Antioxidant - Polymer Additives

Phosphites are most effective during processing and protect both the polymer and the primary antioxidant. Hydrolytically stable phosphites are the most frequently used processing stabilizers in high-performance additive systems. Thioethers are useful only in increasing the long-term thermal stability in conjunction with phenolic antioxidants. The use of thioethers is limited to areas where ...

Send InquiryAntioxidants | Additives for polymers | ADEKA Polymer

ADEKA Polymer Additives Europe offers a full range of solid and liquid primary and secondary antioxidants. ADEKA Polymer Additives Europe offers a full range of solid and liquid primary and secondary antioxidants. ADEKA Polymer Additives Europe offers a full range of solid and liquid primary and secondary antioxidants. Jump to navigation ...

Send InquiryAntioxidants - CROW

Antioxidants. Polymers will change over time when exposed to radiation, excessive heat and/or corrosive enviroments. These changes are the result of oxidative degradation caused by free radicals which form through hydrogen abstration or homolytic scission of carbon-carbon bonds when polymers are exposed to heat, oxygen, ozone, or light.

Send Inquiry

INTRODUCTION TO POLYMER ADDITIVES AND STABILIZATION

– Primary and secondary antioxidants • Additives can also impart particular properties or effects to a polymer system ¾Colorants ¾Photoinitiators ¾Antistats ¾Antimicrobials • Many additives will transform and/or degrade during use. ¾Each of these products must be taken into consideration when evaluating leachables and extractables.

Send InquiryUse of Antioxidant Masterbatch for Polymer Stabilization

Secondary – used as a process stabilizer. This type of stabilization is an effective way to protect the polymer during processing, especially when the polymer undergoes multiple heat histories. Typical chemistries employed include phosphites or thioesters. Primary/Secondary Combination – Both primary and secondary antioxidants are often ...

Send Inquiry

Antioxidants | Thermal Protection for Plastics | amfine.com

Primary antioxidants, ... Blends of primary and secondary antioxidants often show a synergistic performance superior to either type of antioxidant used alone. For example, blends of hindered phenols and phosphites represent the state-of-the-art for the melt process stabilization of many plastics. ... Special additives known as metal ...

Send InquiryPolymer stabilizers

Light stabilizer are used to inhibit polymer photo-oxidation, which is the combined result of the action of light and oxygen.Like autoxidation this is a free radical process, hence the antioxidants described above are effective inhibiting agents, however additional classes of additives are also beneficial, such as UV absorbers, quenchers of excited states and HALS.

Send Inquiry

Polymer Additives - Primary and Secondary Antioxidants

Polymer Additives - Primary and Secondary Antioxidants. Practically all polymer materials undergo oxidative degradation reactions occurring at one or all of the manufacturing, processing and end-use stages. Antioxidants are highly effective in preventing this degradation to the extent that color development, physical and mechanical property loss is kept within acceptable limits.

Send Inquiry

Secondary Antioxidant - an overview | ScienceDirect Topics

Phosphites, and in particular organophosphorus compounds, are secondary antioxidants that decompose peroxides and hydroperoxides into stable, nonradical products, according to Scheme 4.4.They are extremely effective stabilizers during processing and are normally used in combination with a primary antioxidant. Trivalent phosphorus compounds are excellent hydroperoxide decomposers.

Send InquiryPrimary Antioxidants: Antioxidants Selection for Adhesives

Phenolic stabilizers are primary antioxidants that act as hydrogen donors. They react with peroxy radicals to form hydroperoxides and prevent the abstraction of hydrogen from the polymer backbone. Often used in combination with secondary antioxidants, phenolic stabilizers are offered in an extensive range of molecular weights, product forms, and functionalities.

Send Inquiry

BASF Antioxidant - Polymer Additives

Phosphites are most effective during processing and protect both the polymer and the primary antioxidant. Hydrolytically stable phosphites are the most frequently used processing stabilizers in high-performance additive systems. Thioethers are useful only in increasing the long-term thermal stability in conjunction with phenolic antioxidants. The use of thioethers is limited to areas where

Send InquiryAntioxidants | Additives for polymers | ADEKA Polymer

ADEKA Polymer Additives Europe offers a full range of solid and liquid primary and secondary antioxidants. ADEKA Polymer Additives Europe offers a full range of solid and liquid primary and secondary antioxidants. ADEKA Polymer Additives Europe offers a full range of solid and liquid primary and secondary antioxidants. Jump to navigation

Send InquiryAntioxidants - CROW

Antioxidants. Polymers will change over time when exposed to radiation, excessive heat and/or corrosive enviroments. These changes are the result of oxidative degradation caused by free radicals which form through hydrogen abstration or homolytic scission of carbon-carbon bonds when polymers are exposed to heat, oxygen, ozone, or light.

Send Inquiry

INTRODUCTION TO POLYMER ADDITIVES AND STABILIZATION

– Primary and secondary antioxidants • Additives can also impart particular properties or effects to a polymer system ¾Colorants ¾Photoinitiators ¾Antistats ¾Antimicrobials • Many additives will transform and/or degrade during use. ¾Each of these products must be taken into consideration when evaluating leachables and extractables.

Send Inquiry

Antioxidants | Thermal Protection for Plastics | amfine.com

Primary antioxidants, Blends of primary and secondary antioxidants often show a synergistic performance superior to either type of antioxidant used alone. For example, blends of hindered phenols and phosphites represent the state-of-the-art for the melt process stabilization of many plastics. Special additives known as metal

Send Inquiry