optimizing properties for rubber vulcanization at guatemala

Optimizing Properties for Rubber Vulcanization

Optimizing Properties for Rubber Vulcanization It is the responsibility of the formulator to optimize the desired properties for the finished adhesive. This can be done by manipulating the levels of crosslinkers, activators, and accelerators.

Send Inquiry

Optimization of the vulcanization process of rubber

Selection of the optimum conditions for the vulcanization of rubber products, particularly of bulky ones, often is quite difficult. Especially in cases of high demand, it is unavoidable to destruct expensive prototypes in order to check important properties of the rubber at various locations throughout the product.

Send Inquiry

VESTENAMER® in rubber compounds - Additive for the rubber

Tests prove that VESTENAMER® significantly improves the reversion stability of natural rubber, especially at higher vulcanization temperatures. In consequence of the higher molecular weight retained, due to less degradation (during processing) and reduced reversion, when using VESTENAMER®, the static and dynamic properties of the vulcanizates ...

Send InquiryOPTIMIZING THE PROPERTIES OF VULCANIZED COMPOUNDS FOR

The optimal FCBcF, ENR50:SiO2:MgCO3 (100:40:40) with microwave pre-heating at 2.45 GHz and 340 W for one minute before vulcanization, was well cross-linked and strongly converted the microwaves to heat.

Send InquiryVulcanization - an overview | ScienceDirect Topics

Vulcanization. In other rubbers, the reactive site may be a halogen atom, such as in polychloroprene or fluororubbers, or an active hydrogen, as in silicone rubbers. The process of vulcanization does not entirely eliminate all the viscous element of the rubber properties, although the elastic state is more dominant.

Send InquiryStyrene-Butadiene (SBR) Rubber: Uses, Structure & Material

Vulcanization It is a process to obtain cross-linking of elastomer molecules to make rubber stiffer and stronger as well as retains extensibility at the same time. All types of SBR are vulcanized using the same vulcanization agents as for natural rubber. Styrene-butadiene rubber can be vulcanized using sulfur, sulfur donor systems and peroxides. Sulfur is added in slightly smaller amounts than to natural rubber and in tire compounds.

Send InquiryOptimized Cure Times for Rubber Processing – National

called SmartTrac. SmartTrac provides an important new means for rubber product manufacturers to improve the quality of their products while simultaneously reducing cure times. The technology uses in-mold impedance sensors to measure and control the vulcanization of rubber products in real-time.

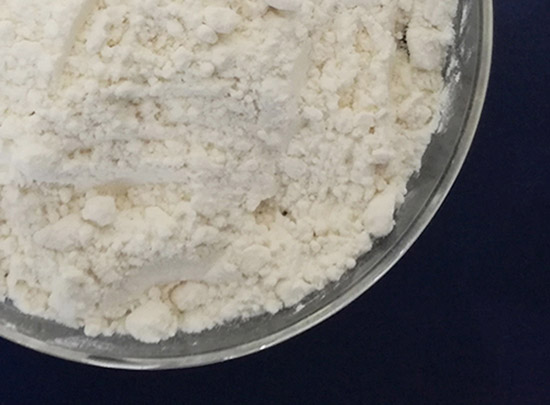

Send InquirySulfur vulcanization

Sulfur vulcanization is a chemical process for converting natural rubber or related polymers into materials of a variety of hardness, elasticity, and mechanical durability by heating them with sulfur or other equivalent curatives or accelerators. Sulfur forms cross-linking bridges between sections of polymer chains which affects the mechanical and electronic properties. Many products are made with vulcanized rubber, including tires, shoe soles, hoses, and conveyor belts. The term vulcanization i

Send Inquiry

Kinetics of Peroxide Vulcanization of Natural Rubber

Organic peroxides can be used for the vulcanization of natural rubber (NR) and for most synthetic rubbers, but the chemistry of crosslinking and properties provided are different. Peroxide vulcanization and the resulting crosslink structure of various rubbers have been studied by a number of researchers [3-10].

Send InquiryComparison of the Vulcanization of Liquid Silicone Rubber

Silicone rubber is a thermoset elastomer having a backbone made up of alternating silicon and oxygen atoms and methyl or vinyl side groups. In this study the vulcanization behaviour of liquid silicone rubber and high consistency rubber was measured and comapred.

Send Inquiry

Optimizing Properties for Rubber Vulcanization

Optimizing Properties for Rubber Vulcanization It is the responsibility of the formulator to optimize the desired properties for the finished adhesive. This can be done by manipulating the levels of crosslinkers, activators, and accelerators.

Send Inquiry

Optimization of the vulcanization process of rubber

Selection of the optimum conditions for the vulcanization of rubber products, particularly of bulky ones, often is quite difficult. Especially in cases of high demand, it is unavoidable to destruct expensive prototypes in order to check important properties of the rubber at various locations throughout the product.

Send Inquiry“Vulcanized rubber-metal bonding, Optimizing adhesion

(Note: “Optimizing adhesion & Cohesion Parameters in Vulcanized rubber-metal bonding” published in Rubber World August 2014 issue, was presented to “the 12 th International Conference on the Science and Technology of Adhesion and Adhesives”, York, UK, September 2013.) “Vulcanized rubber-metal bonding, Optimizing adhesion and cohesion parameters”

Send Inquiry

OPTIMIZING THE PROPERTIES OF VULCANIZED COMPOUNDS FOR

The FCB compound with filler (FCBcF) yielding the best vulcanization time, and the best mechanical, dielectric and dynamic properties, was selected for further study. The optimal FCBcF, ENR50:SiO2:MgCO3 (100:40:40) with microwave pre-heating at 2.45 GHz and 340 W for one minute before vulcanization, was well cross-linked and strongly converted the microwaves to heat.

Send Inquiry

Rubber Vulcanization: Select the Right Vulcanizing Agent

The chemistry of rubber cure or rubber vulcanization is complex. There are several rubber vulcanization systems possible based on reactions with different chemicals. The selection of an accelerator will depend on the specific vulcanizing system. Sulfur vulcanization processes are the most common, but peroxide and metal oxide systems are also

Send InquiryVulcanization - an overview | ScienceDirect Topics

Vulcanization, the introduction of crosslinks into the elastomer's polymer matrix, is a fundamental determinant of rubber properties. In short, it converts a substance that is plastic and moldable into one that is flexible and elastic.

Send InquirySulfur Vulcanization

Vulcanization of rubber by sulfur alone is extremely slow and can take several hours at elevated temperatures (140°C or more). This is problematic because long exposure to temperature and oxygen leads to oxidative degradation which, in turn, results in poor mechanical properties.

Send Inquiry

Sulfur vulcanization

Sulfur vulcanization is a chemical process for converting natural rubber or related polymers into materials of a variety of hardness, elasticity, and mechanical durability by heating them with sulfur or other equivalent curatives or accelerators. Sulfur forms cross-linking bridges between sections of polymer chains which affects the mechanical and electronic properties. Many products are made with vulcanized rubber, including tires, shoe soles, hoses, and conveyor belts. The term vulcanization i

Send Inquiry