milling to soften raw rubber and mix dry ingredients into

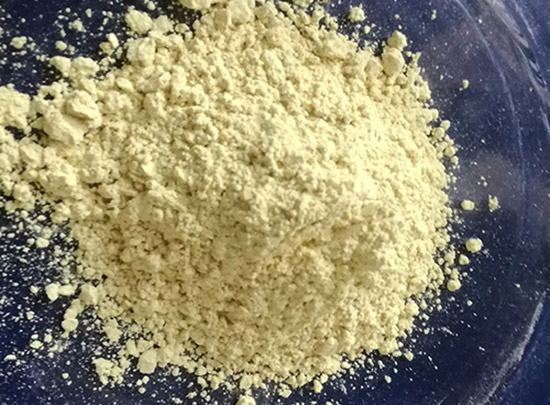

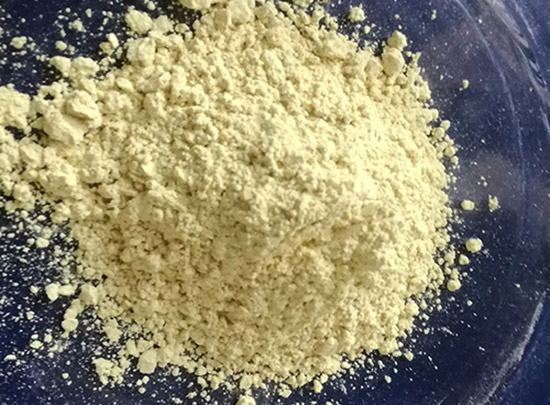

Powder Milling Mixing Machines

The successful mixing of powder is more difficult than mixing liquid, as perfect homogeneity is difficult to achieve. A further problem is the inherent cohesiveness and resistance to movement between the individual particles. The process is further complicated in many systems by the presence of substantial segregation influencing the powder mix.

Send Inquiry

Rubber technology

Milling to soften raw rubber and mix dry ingredients into the compound Methods for processing rubber include mastication and various operations like mixing, calendering , extrusion , all processes being essential to bring crude rubber into a state suitable for shaping the final product.

Send Inquiry

Tender, Fluffy, Yeasted Gluten-Free Cinnamon Rolls | Kitchn

Mix the dry ingredients. Whisk the gluten-free baking flour, salt, and sugar together. This aerates the dry ingredients and evenly distributes all of the flours, leavening, and seasoning for the roll. Add the wet ingredients and stir into a dough.

Send Inquiry

Gluten-free Vegan Sugar Cookies (Oil-free!) - The Vegan 8

To a large bowl, add the dry ingredients and whisk until thoroughly mixed and no lumps remain. Add the syrup, cashew butter and vanilla to the dry ingredients and stir together until it comes together into a ball.

Send Inquiry3 Ways to Soften Cuticles - wikiHow

Coconut oil also helps to strengthen your cuticles. Add 2 drops to each nail bed. Use your thumb to really work the oil into your cuticles. After a thorough massage, put on a pair of rubber or latex gloves to trap the moisture and allow the oil to soak in. Remove the gloves after 10 minutes and wipe off any excess oil that wasn’t absorbed.

Send InquiryDry ingredients equipment - HAAS

Bühler Equipment Mixing & Aerating Systems Wafer Equipment Dry ingredients equipment Dry ingredients equipment - Codos-Mixer The patented Codos System is based on two specially designed mixing screws, which are fitted in a stainless steel mixing chamber.

Send Inquiry

Rawmill

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement mill. The raw milling stage of the process effectively defines the chemistry of the finished cement, and has a large effect upon the efficiency of the whole manufacturing process.

Send Inquiry

Introduction to rubber processing and safety issues

A powered ram or floating weight in the feed throat forces ingredients into the mixing chamber, which is usually water-cooled. The mixed compound is discharged via a sliding or hinged door below the mixing chamber, usually onto a two- roll mill, roller die, twin-screw extruder, conveyor, skip hoist, or wheeled truck.

Send Inquiry32-Ounce Dry Grains Container - Blender Containers | Vitamix

Specially designed blades grind whole grains into fresh flours, mix batter, and simulate the kneading process to easily prepare dough for baking. Engineered for Whole Grains The blades in our Dry Grains Container are specifically designed to create a reverse vortex, pushing dry ingredients away from the blades to prevent packing.

Send Inquiry

Rubber Mixing Mill Video.AVI

Gummi-Misch Walzwerk DEGUMA / Rubber Mixing Mill DEGUMA - Duration: Milling to soften raw rubber and mix dry ingredients into the compound - Duration: 60 POUNDS of Copper Into Ingots.

Send Inquiry

Mixing silicone for compression molding

Milling to soften raw rubber and mix dry ingredients into the compound - Duration: 1:42. Jon Nicholson 504,938 views

Send InquiryHow to mix silicone rubber raw materials by open mill

How to mix silicone rubber raw materials by open mill Fanny Yu. How to insert images into word document table Milling to soften raw rubber and mix dry ingredients into the compound

Send Inquiry

Rubber technology

Milling to soften raw rubber and mix dry ingredients into the compound Methods for processing rubber include mastication and various operations like mixing, calendering , extrusion , all processes being essential to bring crude rubber into a state suitable for shaping the final product.

Send InquiryPowder Milling Mixing Machines

The successful mixing of powder is more difficult than mixing liquid, as perfect homogeneity is difficult to achieve. A further problem is the inherent cohesiveness and resistance to movement between the individual particles. The process is further complicated in many systems by the presence of substantial segregation influencing the powder mix.

Send InquiryIntroduction to rubber processing and safety issues

A powered ram or floating weight in the feed throat forces ingredients into the mixing chamber, which is usually water-cooled. The mixed compound is discharged via a sliding or hinged door below the mixing chamber, usually onto a two- roll mill, roller die, twin-screw extruder, conveyor, skip hoist, or wheeled truck.

Send Inquiry