best sales common vulcanization accelerators crow in liberia

The common accelerators in producing rubber

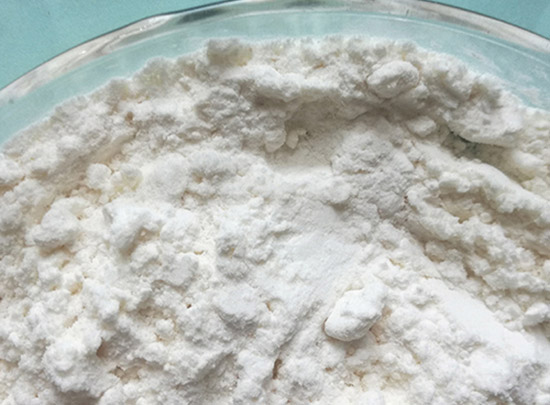

Vulcanization accelerator If it can speed up the curing reaction speed in compound, shorten curing time, reduce curing temperature, reduce curing agent, and can improve or improve vulcanizates of physical and mechanical properties of the material collectively referred to as sulfide accelerator, hereinafter referred to as the rubber accelerator.

Send Inquirydpg d vulcanizing accelerator in Middle East | rubber

Vulcanization Accelerators - CROW. Vulcanization Accelerator. is a compound that increases the speed of vulcanization and that enables vulcanization to proceed at lower temperature and with greater efficiency. Vulcanization accelerators can be classified as primary and secondary accelerators. Important primary accelerators include thiazoles and sulfenamides.

Send Inquiryvulcanization accelerator mbts dm in south east Asia

vulcanization accelerator mbts dm in south east Asia. Common Vulcanization Accelerators. Vulcanization Accelerator. is a compound that increases the speed of vulcanization and that enables vulcanization to proceed at lower temperature and with greater efficiency. Vulcanization accelerators can be classified as primary and secondary accelerators.

Send Inquiry

China Rubber Accelerator TBSI Manufacturers and Suppliers

The results show that Rubber Accelerator TBSI vulcanization rate is similar to that of TBBS, and the scorch is better than TBBS, CZ and TMTD. After vulcanization at 105 °C for 4 h, the 300% proof stress retention rate of vulcanizate with TBSI as promoter is above 70%.

Send InquiryTire and Rubber - Zochem, Inc.

Zinc oxide increases the effect of organic accelerators in rubber vulcanization. Adds strength to rubber compounds, improves their resistance to heat and abrasion and helps guard against ultraviolet degradation. Contributes to the breaking of the accelerator and the sulfur reticulation.

Send Inquiry

Accelerant - The Full Wiki

Sales of any accelerant are limited to the particular group allowed to purchase them for trainings and fire demolitions (to train new firefighters). Accelerators for rubber vulcanization The use of accelerators and activators lowers the activation energy of vulcanization reaction to 80-125KJ/Mole from 210KJ/Mole which is necessary if we use ...

Send InquiryGlobal 1, 3 - Diphenylguanidine Market Size, Market Share

Diphenylguanidine is a very common accelerator for vulcanization of rubber among other accelerators present in the market. Therefore, high demand is reported for 1, 3 - Diphenylguanidine in the global market. 1, 3-diphenylguanidine is widely used in the chemical industry as it is suits all the requirements for a compound to be a primary standard.

Send Inquiry

New vulcanization accelerator from LANXESS| APN News

Cologne – The specialty chemicals company LANXESS has developed a universally suitable vulcanization accelerator for tires and technical rubber goods.The trial product VP Vulkacit TZ, a sulfenamide based on aromatic amines, is suitable for all types of rubber. “We are now inviting our industrial customers to try our new high-performance VP Vulkacit TZ for themselves.

Send InquiryWhat is vulcanised rubber?

Vulcanization or vulcanisation is a chemical process for converting natural rubber or related polymers into more durable materials via the addition of sulfur or other equivalent curatives or accelerators. These additives modify the polymer by form...

Send Inquiry

DIPHENYL GUANIDINE (DPG)

Accelerator, in the rubber industry, is added with a curing agent to speed the vulcanization. Accelerators contain sulfur and nitrogen like derivatives of benzothiazole and thiocarbanilides. The popular accelerators are sulfenamides (as a delayed-action accelerators), thiazoles, thiuram sulfides, dithocarbamates and guanidines.

Send InquiryThe common accelerators in producing rubber

Vulcanization accelerator If it can speed up the curing reaction speed in compound, shorten curing time, reduce curing temperature, reduce curing agent, and can improve or improve vulcanizates of physical and mechanical properties of the material collectively referred to as sulfide accelerator, hereinafter referred to as the rubber accelerator.

Send Inquirytbztd vulcanization accelerator

WESTCO™ TBzTD Accelerator Tetrabenzylthiuram disulfide ; WESTCO™ TBzTD Accelerator Tetrabenzylthiuram disulfide CAS# 10591-85-2 WESTCO™ TBzTD is a fast curing primary or secondary accelerator for NR, SBR and NBR with long scorch times and low to nil nitrosamine generation during vulcanization.

Send Inquiry

dpg d vulcanizing accelerator in Middle East | rubber

Vulcanization Accelerators - CROW. Vulcanization Accelerator. is a compound that increases the speed of vulcanization and that enables vulcanization to proceed at lower temperature and with greater efficiency. Vulcanization accelerators can be classified as primary and secondary accelerators. Important primary accelerators include thiazoles and sulfenamides.

Send Inquiry

New vulcanization accelerator from LANXESS| APN News

Cologne – The specialty chemicals company LANXESS has developed a universally suitable vulcanization accelerator for tires and technical rubber goods.The trial product VP Vulkacit TZ, a sulfenamide based on aromatic amines, is suitable for all types of rubber. “We are now inviting our industrial customers to try our new high-performance VP Vulkacit TZ for themselves.

Send InquiryAMIDINO THIOUREA AS A SECONDARYACCELERATOR IN RUBBER

will depend on the ratio of accelerator to sulphur. Based on the vulcanizate structures, the vulcanizing systems can be classified‘? as a. The conventional vulcanization systems (CV) with very low accelerator: sulphur ratios including unaccelerated sulphur systems b. The efficient vulcanizing (EV) system in which accelerator: sulphur ratio is very high c.

Send InquiryAccelerant - The Full Wiki

Sales of any accelerant are limited to the particular group allowed to purchase them for trainings and fire demolitions (to train new firefighters). Accelerators for rubber vulcanization The use of accelerators and activators lowers the activation energy of vulcanization reaction to 80-125KJ/Mole from 210KJ/Mole which is necessary if we use

Send Inquiry

What is vulcanised rubber? - Quora

Vulcanization or vulcanisation is a chemical process for converting natural rubber or related polymers into more durable materials via the addition of sulfur or other equivalent curatives or accelerators. These additives modify the polymer by form...

Send Inquiry

Research Paper OPTIMIZATION OF VULCANIZATION PROCESS IN

TMTD (0.6 phr) was the best combination of the two accelerators. Results of chemical characterization of vulcanizate networks have been correlated with their technical properties. At higher vulcanization temperature, lower degree of crosslink density and with increasing extent of sulphidic main chain

Send Inquiry