vulcanizaci��n accelerator tbbs accelerator tbbs in philippines

TBBS Accelerator for Rubber

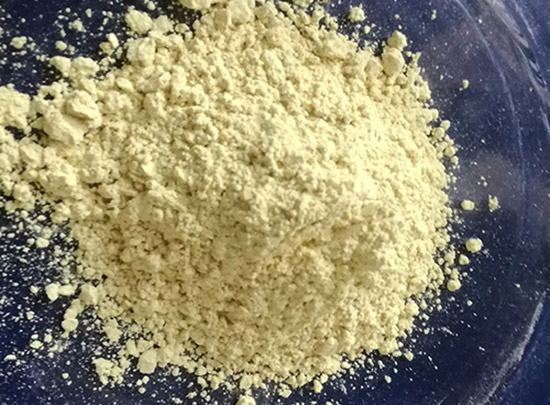

WESTCO™ TBBS Accelerator (N- tert-butyl-benzothiazole sulfonamide) CAS# 95-31-8. It has lower scorch than CBS and can be more safely processed. It has slightly faster scorch than OBTS. WESTCOTM TBBS has high modulus and excellent physical properties, suitable for tire treads and mechanical goods. Solubility: Soluble in ethanol, acetone, benzene, ether, toluene and carbon tetrachloride, practically insoluble in water.

Send InquiryJXBHgran Vulcanization Accelerator TBBS Accelerator TBBS

Product Type: Vulcanization Accelerator Sulfenamides Colloidal Particles TBBS-80 Appearance: Beige particles Density: About 1.09. JIAXING BEIHUA POLYMER ADDITVES CO.,LTD. English. 0086-0573-84639029 ... JXBHgran Vulcanization Accelerator TBBS Accelerator TBBS(NS)-80 ...

Send InquiryVulcanization Chemistry. Comparison of the New Accelerator

The sulfur vulcanization chemistry of cis-polyisoprene formulations accelerated with N-t-butyl-2-benzothiazole sulfenimide (TBSI) is compared to the chemistry of equivalent formulations accelerated with N-t-2-benzothiazole sulfenamide (TBBS).High performance liquid chromatographic analysis (HPLC) is utilized to examine the kinetics of accelerator-sulfur disappearance and the formation ...

Send Inquirylow price granule rubber vulcanizing accelerator tbbs for

low price granule rubber vulcanizing accelerator tbbs for rubber industry. tbbs rubber accelerator, rubber accelerator tbbs price. Click on this page to view the tbbs rubber accelerator structure, specification, properties, application, and to provide quality products at very competitive prices.

Send InquiryRubber Vulcanizing Accelerator TBBS (NS) -Henan GO Biotech

8.Packaging: 25kg plastic woven bag, paper with plastic film bag, Kraft paper bag or jumbo bag 9.Application: Provides fast cure rate and high modulus development in NR, SBR, BR and blends. Normally used alone or with small quantities of ultra accelerators in tire compounds or industrial rubber products low poison and high efficiency.

Send Inquiry

Rubber Accelerator TBBS Market Report – Research, Industry

Get latest Market Research Reports on Rubber Accelerator TBBS. Industry analysis and Market Report on Rubber Accelerator TBBS is a syndicated market report, published as Global Rubber Accelerator TBBS Market Insights, Forecast to 2025. It is complete Research Study and Industry Analysis of Rubber Accelerator TBBS market, to understand, Market Demand, Growth, trends analysis and Factor ...

Send InquiryChina Rubber Accelerator TBSI Manufacturers and Suppliers

The results show that Rubber Accelerator TBSI vulcanization rate is similar to that of TBBS, and the scorch is better than TBBS, CZ and TMTD. After vulcanization at 105 °C for 4 h, the 300% proof stress retention rate of vulcanizate with TBSI as promoter is above 70%. Less than 60% of TBBS.

Send InquiryRubber accelerator DPG Konson Chemical in south east Asia

Rubber accelerator DPG Konson Chemical in south east Asia. Rubber accelerator DPG. It acts as plasticizer and plastic-divider on chloroprene rubber, especially suitable for rubber products such as tire, rubber shoes, and so on.

Send Inquiry

Tbbs/ns Rubber Accelerator - Buy Tbbs/ns Rubber

Tbbs/ns Rubber Accelerator , Find Complete Details about Tbbs/ns Rubber Accelerator,Tbbs/ns Rubber Accelerator,Rubber Accelerator,Tbbs/ns from Plastic Auxiliary Agents Supplier or Manufacturer-Henan GO Biotech Co., Ltd.

Send InquiryVulcanization & Accelerators

vulcanization substantially but at the expense of scorch safety. The dosages of the secondary accelerators are generally between 10-40% of the primary accelerator.

Send Inquiry