theory practice of vulcanization rubber seals in america

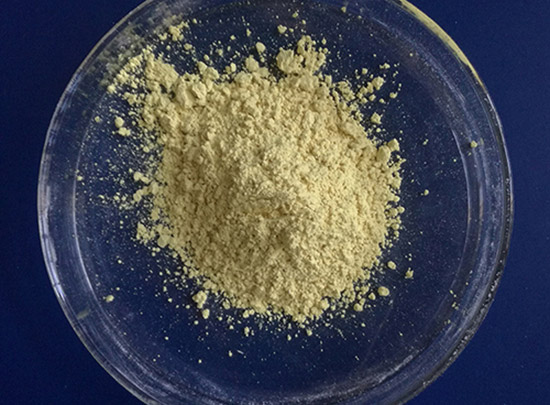

accelerator for rubber vulcanization

Vulcanization of rubber by sulfur alone is an extremely slow process and can take several hours at elevated temperature (140°C or more). This is problematic becasue long exposure to temperature and oxygen leads to oxidative degradation which, in turn, results in poor mechanical properties. It.

Send InquirySulfur vulcanization

Modern developments. Thomas Hancock (1786–1865), a scientist and engineer, was the first to patent vulcanization of rubber. He was awarded a British patent on May 21, 1845. Three weeks later, on June 15, 1845, Charles Goodyear was awarded a patent in the United States.

Send Inquiry

Vulcanization | rubber manufacturing | Britannica

Written By: Vulcanization, chemical process by which the physical properties of natural or synthetic rubber are improved; finished rubber has higher tensile strength and resistance to swelling and abrasion, and is elastic over a greater range of temperatures. In its simplest form, vulcanization is brought about by heating rubber with sulfur.

Send Inquiry

How to Recognize and Avoid the Common Causes of O-ring

The R16 is a pressure buffer seal that protects the primary rod seal from high-frequency pressure spikes. Wiper seal —The Hallite’s E5W is a double-acting, O-ring energized rod wiper seal designed to keep dirt and contaminants out of the cylinder.

Send InquiryCorrelation of results from curemeters of different

ASTM D-2084, standard test method for rubber property - vulcanization using oscillating disk curemeter, was adopted in 1971. It has become a standard test for checking the properties of rubber compounds in factory operations.

Send Inquiry

Rubber Test Types – TA Instruments

Rubber Test Types. TA Instruments’ Rubber Testing Instruments perform a wide array of tests for the measurement of rheological and physical properties of polymers, rubber, and rubber compounds and all stages of manufacture.

Send InquiryElastomer / Rubber Materials Technical Papers

Nitrile Rubber - Past, Present & Future: Vulcanization - Theory of Practice: Theory of Rubber Compounding: Dialkyl Phthalate Plasticizers: Thermal Stability of BPAF and TAIC Cured Fluoroelastomers: Testing and Process Improvement; Beyond Statistical Process Control: Rheology Gives Product Quality A Boost: Implementing SPC in the Materials Control Lab

Send Inquiry

Designing with Rubber

When the mold opens the part can be removed. The excess rubber, called flash, is. Compression molding is the process of placing a pre-load of a rubber material or compound directly in the mold cavity and compressed to the shape of the cavity by the closure of the mold.

Send Inquiry

How to Repair Disintegrating Rubber | Our Pastimes

How to Repair Disintegrating Rubber. Shine with a vegetable oil like almond oil. Rubber trim on old cars may be rejuvenated with a tire dressing product like Back to Black or a rubber dye like Forever Black. Rubber car parts can also be soaked in clean power steering fluid (since the purpose of the fluid is to maintain the rubber seals in the system.

Send Inquiry

Rubber Standards - ASTM International

Rubber Standards. ASTM's rubber standards are instrumental in specifying, testing, and assessing the physical, mechanical, and chemical properties of a wide variety of materials and products that are made of rubber and its elastomeric derivatives. Rubber, which can either be synthetically produced or derived from the milky colloidal suspension found...

Send InquiryTheory & Practice Of Vulcanization - Seals Eastern | PDF4PRO

Theory & Practice Of Vulcanization DANIEL L. HERTZ, JR. SEALS EASTERN INC. RED BANK, NJ 07701 This paper concerns the theory and practice of vulcanization

Send Inquiry

Theory

Theory & Practice Of Vulcanization. Daniel L. hertz, jr. Seals eastern inc. red bankThis paper concerns the theory and practice of vulcanization - the process of adding crosslinks toTheory. A practical rubber product is developed by incorporating crosslinks which chemically tie

Send InquiryVulcanization - an overview | ScienceDirect Topics

Vulcanization is a chemical process in which the rubber is heated with sulphur, accelerator and activator at 140–160°C. The process involves the formation of cross-links between long rubber molecules so as to achieve improved elasticity, resilience, tensile7.2 Definition of Vulcanization.

Send InquiryVulcanization of Rubber | 12th Std | Chemistry | Science | CBSE Board

Our content consists of the entire 12th standard Science syllabus in a fun learning method with various sounds and animations. It is as per the current

Send Inquiry

Sulfur vulcanization

Sulfur vulcanization is a chemical process for converting natural rubber or related polymers into materials of a variety of hardness, elasticity, and mechanical durability by heating them with sulfur or other equivalent curatives or accelerators.

Send Inquiry

Theory & Practice Of Vulcanization

Theory & Practice Of Vulcanization. Daniel L. hertz, jr. Seals eastern inc. red bank, NJThis paper concerns the theory and a deformation is proportional to the Vulcanization, theIt occurs between • Theory of vulcanization polymer backbone between network two statistically

Send InquiryWhat is vulcanised rubber?

Vulcanization or vulcanisation is a chemical process for converting natural rubber or related polymers into more durable materials via the addition of sulfur or other equivalent curatives or accelerators. These additives modify the polymer by forming cross-links (bridges) between individual polymer chains.

Send Inquiry

Vulcanization - Rubber as a natural product - JRank Articles

Vulcanization is the process by which rubber molecules (polymers or macromolecules made of repeating units or monomers called isoprene) are cross-linkedThe process of vulcanization was discovered accidentally in 1839 by the American inventor Charles Goodyear (1800-1860) when he

Send InquiryVulcanization

Vulcanization (British: vulcanisation) is a chemical process, invented by Charles Goodyear, used to harden rubber. Vulcanization traditionally referred to the treatment of natural rubber with sulfur and this remains the most common example

Send InquiryVulcanization of Rubber

Topics under consideration are related to rubber vulcanization and testing of cured elastomers. New ancillary chemicals used in rubber compounds wereThis study examined the effect of ingredients mixing sequence to the vulcanization kinetics of natural rubber. The effects of mixing temperature

Send Inquiry