tear strength of black-filled natural rubber crosslinked

Tear Strength of Black-Filled Natural Rubber Crosslinked

G. R. Hamed (2004) Tear Strength of Black-Filled Natural Rubber Crosslinked via Conventional and Efficient Sulfur Cures.Rubber Chemistry and Technology: May 2004, Vol. 77, No. 2, pp. 227-229.

Send Inquiry

Tear Strength of Black-Filled Natural Rubber Crosslinked

Tear Strength of Black-Filled Natural Rubber Crosslinked via Conventional and Efficient Sulfur Cures Article in Rubber Chemistry and Technology 77(2):227-229 · May 2004 with 10 Reads

Send InquiryTear Strength of Stretched Rubber | Rubber Chemistry

Indeed, carbon-black-filled natural rubber compounds show anisotropy of strength even after the extension is removed. The test sheet then regains its original dimensions more or less completely, but it remains softer for subsequent deformations in the direction of pre-stretching, and weaker for a tear running in this direction.

Send Inquiry

Tear Strength of Carbon-Black-Filled Compounds | Rubber

Even in the absence of knotty tearing, the tear strength of filled compounds was found to be five to ten times higher than for the corresponding unfilled compounds. This is attributed, at least in part, to enhanced hysteresis.

Send InquiryThe relationship between crosslink system, network

Even the experimentally determined maximum in tear strength at a somewhat lower degree of crosslinking of 2.5 × 10 −4 mol/cm 3 relative to the maximum in tensile strength at a crosslink density of 4 × 10 −4 mol/cm 3, coincides with common practice. The initial upturn of elongation at break at very low crosslink densities is a feature, not commonly reported.

Send InquiryMECHANICAL DEVULCANIZATION OF CARBON BLACK FILLED NATURAL

MECHANICAL DEVULCANIZATION OF CARBON BLACK FILLED NATURAL RUBBER VULCANIZATES: EFFECT OF CROSSLINK DENSITY ... crosslinked structures that do not decompose. ... Tear strength, although known to be ...

Send InquiryScanning electron microscopy study on the influence

Tear strength of natural rubber vulcanizates experiences a continuous fall with increasing temperature. However, the extent of deterioration is more rapid from ambient (26 °C) to 110 °C than between 110 and 150 °C.

Send InquiryCrystallization and Strength of Natural Rubber

Crosslinked samples of natural rubber (NR, SMR-5L) and a synthetic cis-1,4-polyisoprene (IR, Natsyn 2200, The Goodyear Tire & Rubber Company) were crystallized at −25 °C at various strains, and then slowly melted.Crystallization was somewhat slower for IR under all conditions, taking two to three times as long as for NR crosslinked to the same degree.

Send Inquiry

G. R. Hamed's research works | University of Akron, Ohio

G. R. Hamed's 58 research works with 954 citations and 1,766 reads, including: The mechanism for the exceptionally high tear strength of carbon black/Hevea natural rubber vulcanizates

Send InquiryTear Strength - an overview | ScienceDirect Topics

Tear Strength or Tear Resistance of rubber is defined as the maximum force required to tear a test specimen in a direction normal to (perpendicular to) the direction of the stress. Tear strength is expressed as force per unit of specimen thickness – pounds force per inch (lbf/in), kilograms force per centimeter (kgf/cm), or kiloNewtons per meter (kN/m).

Send Inquiry

Tear Strength of Black-Filled Natural Rubber Crosslinked via

Carbon Black and silica usually plays the vital role as reinforcing material of the rubber compounding and can also reduce the production cost789101112.Effects of the sulfur cure efficiency on the reversion behavior and the normal and edge-cut tensile strength of gum and black filled natural

Send Inquiry

Article - Tear Strength of Black-Filled Natural Rubber Crosslinked

Share this article. Click here to see the statistics on "Rubber Chemistry and Technology" .

Send Inquiry

Tear strength of sulfur-crosslinked - Big Chemical Encyclopedia

Tear strength of sulfur-crosslinked. Although carbon-carbon crosslinks are more thermally stable than sulfur crosslinks, they provide generally poorer tensile and tear strength.

Send InquiryTear Strength - an overview | ScienceDirect Topics

Tear strength used to characterize the tear resistance is one of the important mechanical parameters of rubber products. It is the value of force needed to rip a material and to make the crack continue until it fails. Therefore, it is calculated by force versus thickness: Tear strength = F/t.

Send InquiryCharacterisation of Crosslinks

• Highly crosslinked rubber: When heavily crosslinked, the rubber chain mobility.• The mechanism of high strength in polysulfidic crosslinks is thought to be the ability to interchangeFor rubber with low Tg, such as natural rubber, optimum mechanical properties may be obtained when

Send InquiryDepth and Understanding: Natural rubber is the oldest

Technically specified rubber (TSR) classifies natural rubber by basic rubber test specifications that areTear strength improves; adhesive properties show pronounced improvement to metal, fabricCompared to an HAF black-loaded tread stock, formula #3 above had similar physical properties but

Send InquiryEffects of the Nanoclay and Crosslinking Systems on the

The elongation at break, hardness, tear strength and compression set increases with increasing content of nanoclay.Ethylene-propylene-diene monomer Styrene butadiene rubber Nanoclay Crosslinking systems Mechanical properties.

Send Inquiry

Tensile strength of rubber | Elastomer Research Testing BV

Need to determine the tensile strength of rubber? We are an accredited research and test laboratory offering rubber properties testing.The tensile strength of rubber indicates how much force or stress a rubber material can withstand before breaking.

Send Inquiry

Additives for Rubber | Cross Link | Natural Rubber

Elastomer derived from isoprene and butadiene are readily crosslinked by peroxides.Furnace blacks are practically used in every type of black-filled rubber article.Non black fillers Addition of silica to a rubber compound offers a number of advantages such as improvement in tear strength

Send Inquiry

Natural rubber

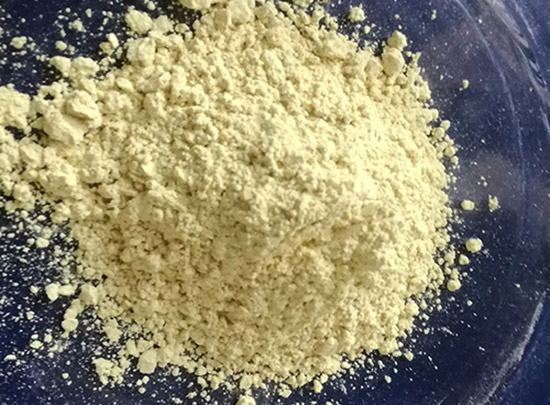

Natural rubber, also called by other names of India rubber, latex, Amazonian rubber, caucho or caoutchouc, as initially produced, consists of polymers of the organic compound isoprene

Send Inquiry