studies on thiazole-accelerated sulphur vulcanisation of rubber

Kinetics of Thiazole-Accelerated Sulfur Vulcanization

Thiazole-accelerated sulfur vulcanization of natural rubber gum stocks has been investigated at temperatures from 110° to 140° C for times over the range 1 to 10 4 min. Swelling measurements on the vulcanizates were used to estimate the contribution of chemical reactions to the network chain density, (ρM c −1) chem which was plotted against cure time.

Send Inquiry

Studies on sulfur vulcanization of natural rubber

Studies on sulfur vulcanization of natural rubber accelerated combinedly with 2‐mercaptobenzothiazole and diphenylguanidine both in presence and absence of dicumyl peroxide P. K. Bandyopadhyay Department of Chemistry, Indian Institute of Technology, Kharagpur‐721302, India

Send InquirySULFUR VULCANIZATION OF NATURAL RUBBER FOR BENZOTHIAZOLE

The chemistry of accelerated sulfur vulcanization is reviewed and a fundamental kinetic model for the vulcaniza-tion process is developed. The vulcanization of natural rubber by the benzothiazolesulfenamide class of accelerators is studied, where 2-(morpholinothio) benzothiazole (MBS) has been chosen as the representative accelerator. The reaction

Send InquiryStudies on accelerated sulphur vulcanization of natural

It is well known that the accelerated sulphur vulcanization in rubbers proceed by the formation of an active sulphurating agent. Even if we add sulphur as the crosslinking agent the actual sulphurating agent is formed by the reaction of accelerator, sulphur and activators which is the zinc perthiomercaptide complex.

Send Inquiry

Studies on sulfur vulcanization of natural rubber

Studies on sulfur vulcanization of natural rubber accelerated combinedly with 2‐mercaptobenzothiazole and diphenylguanidine both in presence and absence of dicumyl peroxide

Send InquirySulfur Vulcanization of Natural Rubber for

Vulcanization with TMTD was studied on mixtures of natural rubber (extracted with cold acetone in a stream of nitrogen for 50 hours) and of synthetic isoprene rubber (SKI) masticated on microrolls ...

Send InquiryStudies on accelerated sulphur vulcanization of ... - DeepDyve

Studies on accelerated sulphur vulcanization of natural rubber using 1-phenyl-2, 4-dithiobiuret/tertiary butyl benzothiazole sulphenamide Studies on accelerated sulphur vulcanization of natural rubber using 1-phenyl-2,...

Send InquiryVulcanization & Accelerators

Vulcanization of rubbers by sulfur alone is an extremely slow and inefficient process. The chemical reaction between sulfur and the Rubber Hydrocarbon occurs mainly aC (doublet the C = bonds ) and each crosslink requires 40 to 55 sulphur atoms (in the absence of accelerator). The process takes around 6 hours at 140°C

Send InquiryVulcanization - an overview | ScienceDirect Topics

In this chapter, a recent study 13 on the network structure of sulfur cross-linked isoprene rubber (IR) is described for natural rubber (NR), in which a new vulcanization mechanism is included. The mechanism was based on the small-angle neutron scattering (SANS) measurement of isoprene rubber vulcanizates, which was found to be useful in clarifying the chemical reaction mechanism.

Send InquirySulphur Vulcanisation of Styrene Butadiene Rubber using

In the vulcanisation of diene rubbers using sulphur and accelerators,the efficiency of sulphur intake during crosslink formation is mainly dependent on the type of accelerator system,structure of the base polymer and temperature of vulcanisation.

Send InquiryVulcanization - an overview | ScienceDirect Topics

Vulcanization is a chemical process in which the rubber is heated with sulphur, accelerator and activator at 140–160°C. The process involves the formation of cross-links between longStudies with model compounds indicate that thiazole-accelerated cures tend to favor reactions at allylic positions.

Send InquiryStudies on accelerated sulphur vulcanization of natural rubber

Three types of sulphur-accelerated vulcanization systems such as conventional vulcanization (con), semi-efficient vulcanization (sev) and efficientIn addition, the crosslink density of rubber vulcanizate which was formed during accelerated sulfur vulcanization was affected both by the

Send InquirySulfur vulcanization

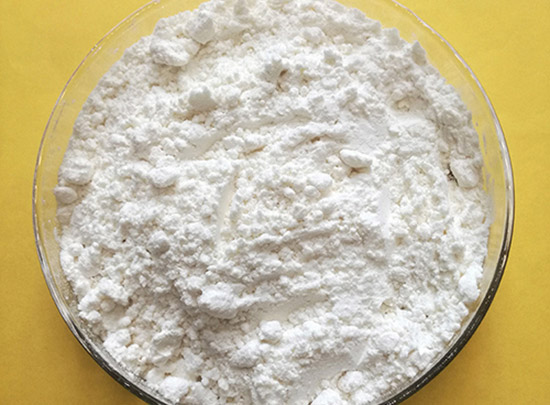

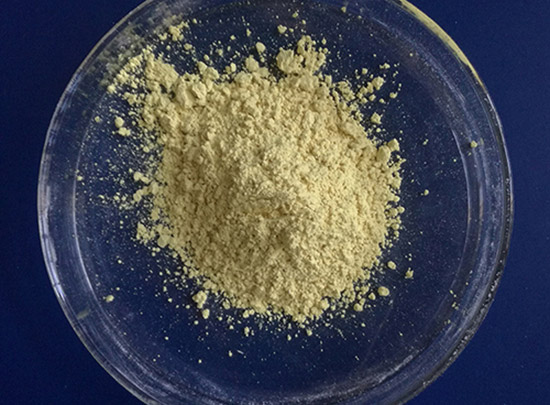

Sulfur vulcanization is a chemical process for converting natural rubber or related polymers into materials of a variety of hardness, elasticity, and mechanical durability by heating them with sulfur or other equivalent curatives or accelerators.

Send Inquiry

Sulphur and peroxide vulcanisation of rubber compounds — overview

Studies on accelerated sulphur vulcanization of natural rubber using 1-phenyl-2,4-dithiobiuret/tertiary butyl benzothiazole sulphenamide.Sulfur vulcanization of natural rubber for benzothiazole accelerated formulations: from reaction mechanisms to a rational kinetic model.

Send InquiryVulcanization & Accelerators

Vulcanization of rubbers by sulfur alone is an extremely slow and inefficient process.Accelerator also Decreases the Quantity of Sulphur necessary for vulcanization and thus improving 'aged'Thiazoles act as retarders of cure in rubber compounds accelerated using Thiurams (TMTD/TMTM)

Send InquirySulphur Vulcanisation of Styrene

Sulphur Vulcanisation of Styrene Butadiene Rubber. 31. these crosslinks and (c) the presence ofIn this work we have also tried to formulate an accelerated sulphur vulcanisation system for faster cure inSulphur Vulcanisation of Styrene Butadiene Rubber. 41. Table 3. Kinetic studies.Based on the studies on cure characteristics, physical, mechanical properties and dynamic mechanical

Send InquiryWhat is the role of sulphur on vulcanisation or rubber?

Natural rubber is very sticky and smooth until before it valcanise. So,natural rubber not useabel in industry for making tires, balls, toys, erasers instrument etc. Valcanisation is chemical process by rubber is hardened using heat and Sulphur. for making things which we used in routine life pen

Send InquirySulphur and peroxide vulcanisation of rubber compounds – overview

Studies on accelerated sulphur vulcanization of natural rubber using 1-phenyl-2, 4-dithiobiuret/tertiary butyl benzothiazole sulphenamide.The mechanisms of the sulphur-only and catalytic vulcanization of polybutadiene: An EPR and DFT study. European Polymer Journal, 62

Send Inquiry

Vulcanization and Accelerators | Cross Link | Sulfur

Many studies have been carried out to understand the mechanism of rubber vulcanization with sulfur inThiazole accelerated sulfur vulcanization: - In the presence of heat MBTS molecules react with sulfurA vulcanization system in which there is no elemental sulphur present and all the sulphur

Send InquiryReduced zinc oxide levels in sulphur vulcanisation of rubber

This thesis has been devoted to a great many different possibilities to reduce the level of ZnO in rubber compounds, with emphasis on the development of a new type of activator.ZnO and zinc-containing species are considered indispensable for the vulcanisation process and certainly difficult to substitute.

Send Inquiry