optimal bleaching performance of acid activated ?ngwulangwu? clay

Optimal Bleaching Performance of Acid Activated

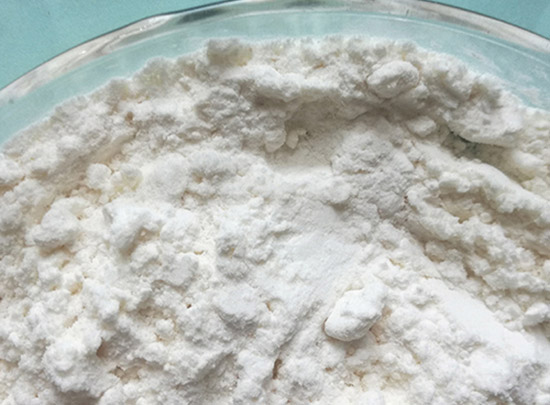

D. Acid Activation of the Clay The purified clay was ground and sieved using 180µm sieve size followed by treatment with 1.5M H2SO4 at acid to clay ratio of 2:1. The activation was carried out in a round bottom flask with reflux. The slurry was continuously stirred at temperature of 90oC for 3 hours.

Send Inquiry

Determination of the Optimal Process Conditions

the deodorized oil colour reached a maximum when the bleaching temperature is about 100oC. Oil – adsorbent ratio, is also of importance in determining the optimum performance condition of clay during bleaching, as it affects the efficiency of degumming and bleaching processes.

Send InquiryOptimization of Bleaching Process

Optimal moisture levels are typically less than equal weight of the bleaching clay dosage and more likely to be around 0.2 to 0.3 weight % [11-13]. Figure 12 . Oil moisture effects: in bleaching refined (neutralized) soybean oil (RSBO) at 115°C, with 1.5% clay dosage, under 125 mmHg vacuum (25 inches Hg absolute pressure) for 45 minutes.

Send Inquiry

OPTIMAL PROCESS PARAMETERS FOR THE ADSORPTION OF METHYLENE

Ejikeme et al [11], had earlier worked on the optimal bleaching performance of acid activated Ngwulangwu clay, using Central Composite Design (CCD) to optimize the process variables. In this work, The physicochemical properties of Enugu White Clay as well as the test palm oil were determined.

Send Inquirypalm oil bleaching process | oil pressing machine supplier

Optimal Bleaching Performance of Acid Activated „Ngwulangwu‟ Clay Ejikeme Ebere M., Egbuna S.O., Ejikeme P.C.N, bleaching efficiency of palm oil using acid activated ‘Ngwulangwu’ clay. Central Composite Design was used to optimize these process conditions (time, temperature and clay dosage) on the bleaching efficiency of the palm

Send Inquiry

Clay Characterization and Optimisation of Bleaching

The optimum bleaching conditions (clay dosage and bleaching time) of 3%/weight of oil and 30 mins resulted in 33.3% CR and %FFA of 2.2. It was discovered that NaOH activated clay resulted to higher %CR while KOH activated clay shows affinity for reduced %FFA but at higher concentration of 5 M.

Send Inquiry

LINEAR PROGRAMMING APPROACH FOR THE DETERMINATION OF THE

The research paper published by #IJSER journal is about LINEAR PROGRAMMING APPROACH FOR THE DETERMINATION OF THE OPTIMAL PROCESS PARAMETERS IN THE PHYSICALLY REFINED VEGETABLE OILS, published in IJSER Volume 6, Issue 1, January 2015 Edition.

Send InquiryResponse Surface Optimization of Palm Oil Bleaching

The clays were acid activated by mineral acids at various temperatures and time period of activations to optimize the best condition for production of good quality bleaching clay. 2M HCl, 1:15 ...

Send InquiryOptimization of Bleaching Process of Crude Palm Oil by

The bleaching of crude palm oil using activated plantain peel ash (APPA) was studied in this work. Historical data design (HDD) in response surface methodology (RSM) experimental design was employed to optimize and correlate the process operating parameters (temperature, time and adsorbent dosage) to the percentage bleaching efficiency. The analysis of the results showed that the quadratic ...

Send InquiryRefining of crude rubber seed oil as a feedstock for

In terms of bleaching process, Egbuna et al. (2015) published that the optimal bleaching efficiency in respect of carotenoid adsorption was 83% which was achieved at 99.83°C for 40 min with 4% of clay dosage in palm oil refining.

Send InquiryOptimal Bleaching Performance of Acid Activated

D. Acid Activation of the Clay The purified clay was ground and sieved using 180µm. sieve size followed by treatment with 1.5M H2SO4 at.desirability of 0.940. This present study confirmed the viability of using acid activated „Ngwulangwu‟ clay in. bleaching palm oil. Fig.2. 3D surface plot of

Send InquiryEjikemeEbere, M., Egbuna, S.O. and Ejikeme, P.C.N. (2013) Optimal

Ejikeme, P.C.N. (2013) Optimal Bleaching Performance of Acid Activated Ngwulangwu Clay.The predicted bleaching efficiency of 74% was in good agreement with the optimum experimentalECF Bleaching with Molybdenum Activated Acid Peroxide and its Impact on Eucalyptus Pulp

Send InquiryCharacterization, Acid Activation, and Bleaching Performance

However, activated bleaching clays show a much higher activity [1]. Richardson [2] reported that activated bleaching earths are produced from clays which generally contain high proportions of montmorillonites through acid activation. Often times, clays exhibiting high natural bleaching power

Send Inquiry

Determination of the Optimal Process Conditions for the Acid

The clay was first, acid activated and characterized, and used in the investigation. Central Composite Design (CCD)[17], had earlier worked on the optimal bleaching performance of acid activated Ngwulangwu clay, using Central Composite Design (CCD) to optimize the process variables.

Send InquiryDeterioration of bleachability index pada crude palm

Optimal bleaching performance of acid activated 'Ngwulangwu' clay. International Journal of Engineering and Innovative Technology, 3, 13-19. Some qualiity parameters of crude palm oil from major markets of.

Send Inquiry

Optimal Process Parameters for the Adsorption of Methylene Blue

Ejikeme et al [11], had earlier worked on the optimal bleaching performance of acid activated Ngwulangwu clay, using CentralThe optimal process parameters on the adsorption efficiency of activated Enugu White Clay and on the bleaching performance of palm Oil, has been investigated.

Send InquiryOptimization of Acid Activation Conditions for Athi River

The activated clay samples were labelled A1, A2, A3, A4 and A5 where the numbers in these labels referred to the molarities of the acid used.170, 2011, 90–106 [7] E.M. Ejikeme, S.O. Egbuna, P.C.N. Ejikeme, Optimal bleaching performance of activated „Ngwulangwu‟ clay, IJEIT, 3(5), 2013

Send InquiryDetermination of the Optimal Process Conditions for the Acid

The clay was first, acid activated and characterized, and used in the investigation. Central Composite Design (CCD)[17], had earlier worked on the optimal bleaching performance of acid activated Ngwulangwu clay, using Central Composite Design (CCD) to optimize the process variables.

Send Inquiry

Bleaching of mustard oil with some alternative bleaching

acid activated rice husk ash (AC), rice husk silica (S), and Al(OH)(3) gel to replace commercial Acid Activated Clay (AAC, like Tonsil Earth: TE) for bleaching of mustard oil. Quantities of AAC used were varied from 0.5 to 2.0 % (w/w). It was used as such and along with commercial activated carbon

Send Inquiry

Bleaching Properties of Alumina-Pillared Acid-Activated

The bleaching of cottonseed oil by alumina-pillared (Al-pillared) acid-activated clays was investigated. Acid activation of a Ca-rich montmorillonite (CMS STx-1) following treatment withDirect comparison to the performance of a commercial bleaching earth (Tonsil Optimum 214, Sud-Chemie AG.

Send Inquiry