how to manufacture rubber processing, chemicals, rubber

The Manufacturing Process of Rubber | Sciencing

Natural Rubber. Natural rubber comes from latex, a milky substance produced by rubber plants. The Pilot Products manufacturing firm says that to tap the trees, rubber workers fasten cups to the trunk, then drive a spout into the bark. Latex spurts out under pressure and can run through the spout for 4 hours.

Send InquiryRubber - Processing | Britannica

Rubber processing consists of four basic steps: (1) mastication, when the elastomer is sheared and the molecules are broken down to give easier flow, (2) mixing, usually carried out immediately after mastication, when additives are incorporated, (3) shaping of the viscous mass, for example, by extrusion or molding, and (4) curing, when the polymer molecules become interlinked and the shape is fixed.

Send InquiryHow to Manufacture Rubber Processing Chemicals

automobiles. Rubber processing chemicals play a crucial role in enhancing the properties of rubber for its use in the manufacturing of automotive tires. Thus, the growing automobile industry is projected to boost the overall growth of rubber processing market. www.entrepreneurindia.co

Send InquiryThe 4 Most Common Rubber Manufacturing Processes - The

Each manufacturing process has particular benefits that make it the ideal choice for manufacturing certain types of products. Knowing the manufacturing processes can help you understand cost implications and tradeoffs. Some of the most common rubber manufacturing processes are extrusion, latex dipping, molding, and calendering.

Send InquiryHow to Make Natural Rubber Latex at Home | FeltMagnet

To make rubber at home, you would need following things: Rubber tree sap, freshly taken from the tree. Juice taken from the morning glory plant. A knife. A tapping spout. A wooden stick. A bucket. And a container.

Send InquiryRUBBER PROCESSING TECHNOLOGY - 國立中興大學

Rubber Processing and Products •Many of the production methods used for plastics are also applicable to rubbers •However, rubber processing technology is different in certain respects, and the rubber industry is largely separate from the plastics industry •The rubber industry and goods made of rubber are dominated by one product: tires

Send Inquiry

Rubber Processing Chemicals Market To Reach US$5.1 Bn by

Use of rubber processing chemicals make tires durable and provides them strength to withstand harsh environment. On account of these, the demand from tire industry is the dominant contributor to the market. As per TMR, the tire segment held over 70% of the overall rubber processing chemicals market in 2015.

Send InquiryHow rubber band is made - manufacture, used, processing

This process, which Goodyear dubbed vulcanization after the Roman god of fire, enabled the modern rubber industry to develop. The first rubber band was developed in 1843, when an Englishman named Thomas Hancock sliced up a rubber bottle made by some New World Indians.

Send Inquiry

Chemicals Used in Rubber Tire Manufacturing | It Still Runs

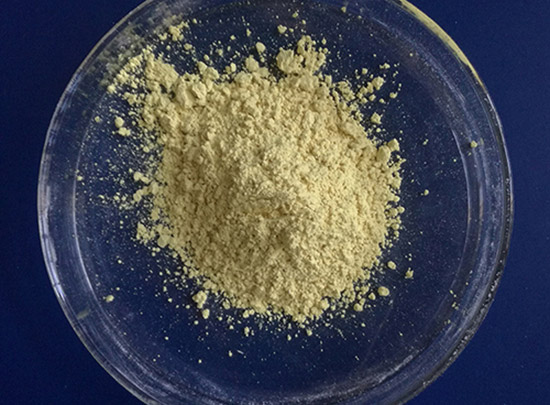

Sulfur. Sulfur is a key component in tire manufacturing. Tires are made out of a product known as vulcanized rubber. The vulcanization process is what makes the tires hard and heat resistant. This works partly because of the mixture of sulfur into the rubber. This is one of the chemicals present in most types of tires,...

Send Inquiry

Natural rubber

Naturally coagulated rubber (cup lump) is used in the manufacture of TSR10 and TSR20 grade rubbers. Processing for these grades is a size reduction and cleaning process to remove contamination and prepare the material for the final stage of drying. The dried material is then baled and palletized for storage and shipment. Vulcanized rubber

Send Inquiry

How to manufacture Rubber Processing, Chemicals, Rubber

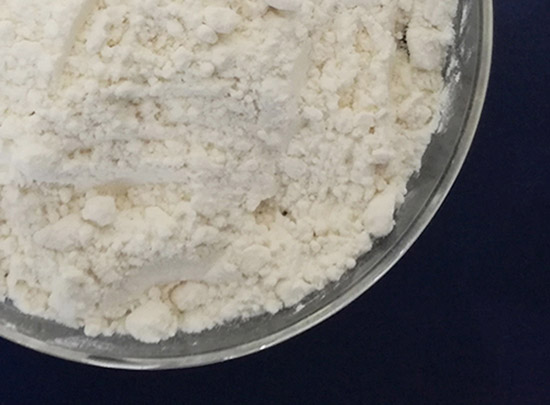

Y_925 How to manufacture Rubber Processing Chemicals, Rubber Additives, rubber chemical additives (Waxes, Amines, Synthetic Organic Chemicals, Silicone

Send InquiryHow to manufacture Rubber Processing | chemical.report

Rubber processing chemicals play a crucial role in enhancing the properties of rubber for its use in the manufacturing of automotive tires. Thus, the growing automobile industry is projected to boost the overall growth of rubber processing market. Rubber processing chemicals not only adds superior

Send Inquiry

The Manufacturing Process of Rubber | Sciencing

The natural rubber manufacturing process begins with harvesting latex from rubber trees.Compounding adds chemicals and other additives to customize the rubber for the intended use. Natural rubber changes with temperature, becoming brittle with cold and a sticky, gooey mess with

Send Inquiry

How rubber band is made - manufacture, used, processing, product

Goodyear, Hancock, and Perry, manufacturing effective rubber bands became possible. In the late nineteenth century, British rubber manufacturers beganSample rubber bands from each batch are subjected to a variety of quality tests. One such test measures modulus, or how hard a band snaps

Send Inquiry

Tire manufacturing

Pneumatic tires are manufactured according to relatively standardized processes and machinery, in around 455 tire factories in the world.

Send Inquiry

Processing and Profiting from Rubber | HowStuffWorks

Processing natural rubber consists of the following stepsSynthetic rubber polymers are made from petroleum-based chemicals, clumped and dried for transport. Once at a manufacturing plant, the synthetic rubber polymers are mixed, ingredients may be added and the rubber is rolled into sheets.

Send Inquiry

Rubber - Processing | Britannica

Rubber - Rubber - Processing: Rubber processing consists of four basic steps: (1) mastication, when the elastomer is sheared and the molecules areMastication and softening are usually carried out in batches. The operation is done either in large enclosed mixing machines or on rubber mills.

Send Inquiryrubber-processing chemical - definition - English

rubber-processing chemical in English.• manufacturing rubber processing chemicals and plasticizers, whether separate chemical elements or compounds (NAICS 32519, Other Basic Organic Chemical Manufacturing) or mixtures (NAICS 32599, All Other Chemical Product Manufacturing)

Send Inquiry

How to manufacture rubber processing chemicals

Find here online price details of companies selling Rubber Chemicals. Get info of suppliers, manufacturers, exporters, traders of Rubber Chemicals for buying in India.

Send InquiryRubber - Chemistry Encyclopedia - structure, reaction, water, uses

Natural rubber is one of nature's unique materials. The Native Americans of tropical South America's Amazon basin knew of rubber and its uses long before Christopher Columbus's explorations brought it to the attention of Europeans. The Indians made balls of rubber by smoking the milky, white latex of

Send Inquiry