effect of curing agent dtdm on properties of vulcanized

Effect of Curing Agent DTDM on Properties of Vulcanized

The effect of curing agent DTDM on properties of vulcanized EPDM was studied as the using level of sulfur were 0 phr and 0.5 phr.The results showed that the compound based on EPDM had lower curing rate,longer pre vulcanization time and better mechanical properties when DTDM was used without sulfur.While little sulfur was added to the curing system ...

Send Inquiry

Effect of vulcanization systems on properties

Conclusions. As a consequence, higher interaction between vulcanized ENR-30 domains and PP matrix is expected. This is a reason for higher rheological, mechanical properties and elastic modulus as well as for lower damping factor and tension set values for the TPVs with phenolic containing cure systems.

Send InquiryThe Effect of the Vulcanizing System on Cure

The Effect of the Vulcanizing System on Curing and Mechanical Properties of NBR/EPDM Blends again. The swollen and de-swollen weights were used to calculate the volume fraction of rubber in the network when swollen to equilibrium, V r, according to the following expression: where: D = de-swollen weight, S = swollen weight, ρr

Send Inquiry

EFFECT OF CURING SYSTEMS ON MECHANICAL PROPERTIES AND N

effect of curing systems on mechanical properties and n-pentane resistance of carbon black filled natural rubber vulcanizate. EV, Semi-EV and sulfur donor type of vulcanization system were used to investigate this phenomena. The curing characteristics and crosslink density were also measured to accomplish this investigation. 1.

Send InquiryEffect of different types of peroxides on properties

Effect of Different Types of Peroxides on Properties of Vulcanized EPDM + PP Blends Witold Brostow, Tea Datashvili, Ken P. Hackenberg Department of Materials Science and Engineering, Laboratory of Advanced Polymers and Optimized Materials (LAPOM), University of North Texas, Denton, Texas 76203-5017 Mechanical and tribological behavior of several aimed at selectively crosslinking the dispersed rubber dynamic vulcanizate blends of polypropylene (PP) with phase, without an extensive propagation ...

Send InquiryVulcanization & Accelerators

Sulfur as vulcanizing agent has a limitation that, the elastomers must contain chemical unsaturation (C=C double bonds) for cross linking. The structure of speciality elastomers EPDM and Butyl had to be sulfur chemically modified to make sulfur vulcanization possible for their commercial success.

Send Inquiry

Rubber Vulcanising Agent Dtdm,Rubber Chemical Agent,Dtdm

This kind of free radical can not only resist heat and oxygen, but also delay coking time, so that speed up vulcanization. So, DTDM has a performance of vulcanized agent, promoter, anti oxidantand prevent coking comprehensive effect. So many rubber product enterprise including domestic and overseas pay attention to DTDM.

Send InquiryHigh-performance curing systems

Under normal curing conditions, free sulfur is released which, in contrast to normal sulfur, mainly forms mono- and di-sulfidic bridges. Because of their higher bond energies, these di-sulfidic bridges are much more resistant to reversion and are responsible for the excellent heat-aging resistance of the vulcanizates.

Send InquiryEffect of vulcanization systems on properties

Effect of vulcanization systems on properties and recyclability of dynamically cured epoxidized natural rubber/polypropylene blends Article in Polymer Testing 27(7):858-869 · October 2008 with ...

Send Inquiry

Effect of curing agent on the properties of mineral silica

The effect of the epoxy molecular architecture on the reactivity with amine curing agents has been studied using different, epoxy-containing compounds with various configurations.

Send InquiryEffect of Sulfur Donor on Properties of Thermoplastic Vulcanizates

Three types of vulcanizing agent (i.e., Tetramethyl thiuram disulfide (TMTD), 4,4 Dithiodimorpholine (DTDM) and Dipentamethylene thiuram tetrasulfide (Tetrone A)) were used to cure the rubber phase ofThe curing systems did not affect the hardness properties and solvent resistance of the TPVs.

Send InquirySulfur vulcanization

Vulcanization, in common with the curing of other thermosetting polymers, is generally irreversible. However, significant efforts have focussed on developing 'de-vulcanization' processes for recycling of rubberSulfur, by itself, is a slow vulcanizing agent and does not vulcanize synthetic polyolefins.

Send InquiryVulcanizing Agent Dtdm(id:10268662). Buy China

3500 USD. So, DTDM has a performance of vulcanized agent , promoter, anti oxidantand prevent coking comprehensive effect. So many rubber products manufacturers including domestic and overseas pay attention to DTDM.

Send Inquiry

Vulcanizing Agent DTDM Products

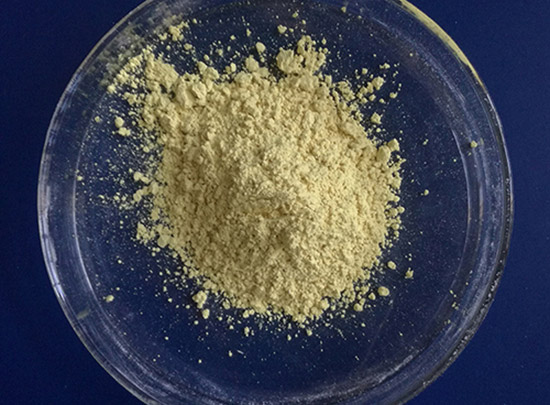

Vulcanizing Agent DTDM Chemical Name: 4,4'-dithiodimorpholine CAS NO: 103-34-4 Properties: White crystalline or powder.It will release a percentage of 27 active sulphur in the temperature of vulcanization; It will produce a high connecting effect to the rubber, part or whole replace the sulphur

Send Inquiry

rubber vulcanizing agent DTDM/rubber curing agent DTDM

Properties: White crystalline or powder. Specific gravity: 1.32-1.38.This kind of free radical can not only resist heat and oxygen, but also delay coking time, so that speed up vulcanization. So, DTDM has a performance of vulcanized agent, promoter, anti oxidantand prevent coking comprehensive effect.

Send InquiryVulcanising Agent DTDM

Vulcanising Agent DTDM, Rubber Vulcanising Agent, rubber product manufactrue.Application: It is used as the rubber accelerator and vulcanized agent of natural rubber, synthetic rubber. Under the curing temperature, it can release active sulfur, effective sulfur content is about 27%.

Send InquiryVulcanization - an overview | ScienceDirect Topics

Vulcanization, thus, is a process of chemically producing network junctures by the insertion of crosslinks between polymer chains. A crosslink may be a group of sulfur atoms in a short chain, a single sulfur atom, a carbon-to-carbon bond, a polyvalent organic radical, an ionic cluster, or a polyvalent

Send InquiryPre-dispersed curing agent Dithiodimorpholine DTDM-80

curing agent Dithiodimorpholine DTDM-80 Manufacturers & Suppliers, find Pre-dispersed curing agent5. PROPERTIES: DTDM is a free sulfur donor under normal curing conditions.Product Categories : Polymer-bound pre-dispersed rubber chemicals > Vulcanizing Agent.

Send Inquiry

Vulcanizing Agent DTDM

Vulcanizing Agent DTDM / Properties: White crystalline or powder.Application: Sulphur donor vulcanizing agent for efficient vulcanization and semi-efficient vulcanization cure system; provide heat/reversion/aging resistance in NR and synthetic rubbers; non-blooming; excellent storage safety.

Send Inquiry

Vulcanizing agent DTDM - China - Manufacturer - Product Catalog

DTDM DOUBLE VIGOUR China, Vulcanizing agent DTDM Synonym: Dithiodimorpholine. Property: Crystalline substance,soluble in hot ethyl alcoholAdjusts network structure of vulcanized rubber. Heat,fatigue and reduction resistant.No frosting and no burnt rubber. Ideal vulcanizer for heat resistant

Send Inquiry