doc basic rubber compounding at guatemala

Basic Rubber Compounding Course Conference Registration

Basic Rubber Compounding course ONLY - €1,075 plus German VAT. Receive a discount on the Basic Rubber Compounding course when you also register for a two-day pass to Tire Technology Expo Conference 2020 - €1695 plus German VAT. Please note: your course pass is also valid for FREE ENTRY into the Tire Technology Expo 2020 exhibition on ALL DAYS.

Send InquiryBasic Rubber Compounding Course Multiple Delegate Registration

Basic Rubber Compounding course ONLY - €1,075 plus German VAT. Receive a discount on the Basic Rubber Compounding course when you also register for a two-day pass to Tire Technology Expo Conference 2020 - €1695 plus German VAT. Please note: your course pass is also valid for FREE ENTRY into the Tire Technology Expo 2020 exhibition on ALL DAYS.

Send Inquiry

ASSIST-QuickSearch Document Details

This specification covers accelerated, room temperature curing synthetic rubber compounds used in the sealing and coating of metal components on weapons and aircraft systems for protection against corrosion. The Class 1 sealing compound is effective over a continuous operating temperature range of ¿65° to +250° F (¿54° to +121° C).

Send Inquiry

Introduction to Rubber Technology | 2019 Training Courses

The environmental factors that have the potential to cause degradation of rubber compounds and the effects that heat agency has on the network and finished properties. Methods of protection are described. Recycling and Re-use of Waste Rubber . An overview of recycling rubber and the waste rubber market.

Send Inquiry

Rubber Material Selection Guide EPDM or Ethylene Propylene

formulate an EP or ethylene eropylene rubber compound to meet your specific application and performance requirements, please contact Robinson Rubber Products at e-mail: sales@robinsonrubber.com or phone: +1-763-535-6737. Robinson Rubber Products Company, Inc. makes no expressed or implied warranty as to any qualities, attributes, or

Send Inquiry

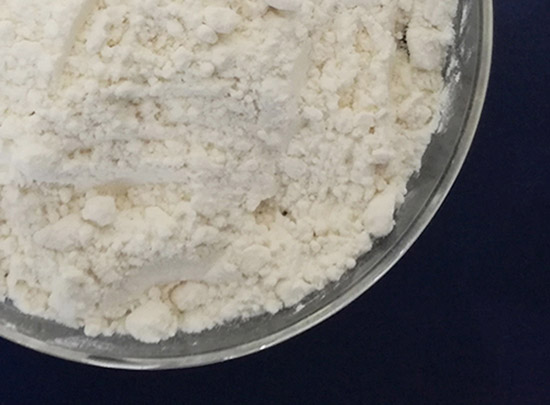

NON-BLACK FILLERS FOR ELASTOMERS

the major reinforcing filler for tires and many other rubber and plastic products. However, carbon black impose a restriction on the color of the vulcanized products. On the other hand, non-black fillers offer the possibility that any color can be mixed in and be seen in the products. Non-black fillers can

Send InquiryRubber Selection Guide CSM or Hypalon Chlorosulphonated

formulate a CSM or Hypalon / chlorosulfunated-polyethylene rubber compound to meet your specific application and performance requirements, please contact Robinson Rubber Products at e-mail: sales@robinsonrubber.com or phone: +1-763-535-6737.

Send Inquiry

Rubber Compounds - A Market Opportunity Study - September 2011

extenders and fillers in rubber compounds in end use applications. Specific product and performance information needs are highlighted in the Product and Market Development Strategies for Soy Products in Rubber Compounds section later in this report.

Send Inquiry

Home | Rubber Technology

Rubber Technology. ERIKS is a leading company in the field of rubber technology for practically all industries. We are your partner for supplying all possible rubber products; from more standard products like grommets and bellows to custom designed geometries and materials.

Send InquiryThe Physical Properties of Rubber - SlideShare

The Physical Properties of Rubber 1. The Physical Properties of RubberRick Hudson 2. Visco-ElasticityVisco-ElasticityThis is because an elastomer goes throughboth a viscous phase and an elastic phase.An elastomer is a visco-elastic material.Spring & DashpotThe visco-elastic behavior of elastomerscan be simulated using a spring coupledwith a dashpot (damper). The springillustrates the elastic ...

Send Inquiry

6.RUBBER COMPOUNDING TECHNOLOGY-FINAL.ppt

RUBBER COMPOUNDING OBJECTIVE 1. To secure certain properties in the finished product to satisfy the service requirements. 2. To attain processing characteristics necessary for efficient utilization of available equipment. 3. To achieve desirable properties and processability at the lowest cost.

Send Inquiry91637420-Rubber-Compounding.pdf | Natural Rubber | Petroleum

The Basic Rubber Compound. 6.RUBBER COMPOUNDING TECHNOLOGY-FINAL.ppt.medical devices, bumpers, and numerous other products. Compounding is a term that has evolved within the plastics and rubber industry and in many respects is a misnomer for the material science of.

Send InquiryBasic rubber compounding | rubber compounding basics

In developing a rubber compound, it is essential to mix the raw dry rubber with various compounding ingredients.The most common compounding ingredients added into the rubber are vulcanizing agents, vulcanization accelerators, activators for the accelerators, fillers, processing aids, softeners

Send Inquiry

RUBBER COMPOUNDING BASICS | Rubber Compounding Made

Sheet out the compound by pressing it with your hands against the roll and allow it to roll back into itself to become a long cylindrical roll.These allow compounding ingredients to be homogeneously distributed into the rubber. Masticated rubber is softer and flows more easily than in its original state.

Send InquiryRDI Technical: Basic Rubber Compounding

Basic Rubber Compounding. Intro. 5 main systems. Guide.Not only can we improve an elastomer’s physical strengths by compounding other ingredients into the mixture of elastomer and sulfur, but also we can improve other characteristics and even create some that do not naturally occur.

Send InquiryHEXPOL Rubber Compounding

HEXPOL Rubber Compounding is a leading developer and manufacturer of advanced, high-quality rubber compounds by using innovative processes and state-of-the-art equipment. Customers of the HEXPOL Rubber Compounding business area comprise rubber product manufacturers who place

Send InquiryPreview: Basic Rubber Compounding Course at Tire Technology Expo

The Basic Rubber Compounding Course will take place parallel to the Tire Technology Expo from 19 - 20 February 2018 in Hanover, Germany. It is designed for all those working in the associated tyre industries, who wish to know more about the compounding of rubber. The course will be presented

Send Inquiryrubber compounding process - Bing

Rubber compounding or formulation refers to the addition of certain chemicalsResins and rubber additives are purchased direct from major suppliers throughout Europe and the US to be added to raw materials for the Primary Compounding process.

Send InquiryElastomers and Rubber Compounding Materials - 1st Edition

4.11.7 Compounding and properties of CM. 4.12 Polyacrylate rubber.6.6.3 Effect of the character of the plasticizer on the properties of the compounds of the rubber vulcanizates.Chapter 7. Textile Materials for Rubber Reinforcement. 7.1 Introduction. 7.2 Basic classification of fibres.

Send Inquiry

Rubber Compounding - an overview | ScienceDirect Topics

Rubber compounding or formulation refers to the addition of certain chemicals to raw rubber in order to obtain the desired properties. The well-known chemicals are crosslinking agents, reinforcements, anti degradants and colorants. The crosslinking agents are required for establishing the crosslinks to

Send Inquiry