rubber_vulcanization_accelerators in nigeria

Devulcanization - VIRGIN RUBBER ALTERNATIVE

Hello! We are an environmental technology company engaged in R&D and production of innovative natural and synthetic rubber alternatives.. In 2014 we invented a new raw material called NGR - Next Generation Rubber.. NGR can replace up to 70% of natural & synthetic rubber of your product.

Send InquiryConveyor Belt Splicing And Vulcanization - ASGCO | ASGCO

Conveyor Belt Splicing and Vulcanization. ASGCO ® is a certified belt splicing company and continues to invest in the latest technology of vulcanizing presses and equipment to continually improve our conveyor belt splicing techniques. Our service technicians attend a certified conveyor belt splicing school certification class were they are trained in the latest splice procedures and material ...

Send InquiryGlobal Rubber Vulcanization Market Segment Outlook, Market

The report on Rubber Vulcanization Market offers in-depth analysis of market trends, drivers, restraints, opportunities etc. Along with qualitative information, this report includes the quantitative analysis of various segments in terms of market share, growth, opportunity analysis, market value, etc. for the forecast years.

Send Inquiry

Resins and Building Blocks for Rubber and Tires

Phenolic Resins and Versatic™ Acids for Tire Cord and Rubber. The Bakelite ® family of phenolic resins includes tackifiers, vulcanizing agents, reinforcing resins and Versatic Acids for the manufacture of tires and rubber goods. Hexion has a complete portfolio to meet the growing needs of the tire and rubber industry.

Send InquiryThe adsorption of binary liquid mixtures of amines

preparation of rubber vulcanization accelerators and in the preparation of nikethamide, the diethyl amide of nicotinic acid, which is used medicinally as a respiratory stimulant and analeptic. On the other hand, triethyl amine 1s used as an antigelling agent and viscosity improver in paint .

Send Inquiry

Syntheses, spectroscopic characterization, crystal

These studies showed that the zinc(II)–ditiocarbimates are a new class of rubber vulcanization accelerators, worth of further investigation.

Send Inquiry

Effect of Stearic Acid Level on the Physical Properties

PMB 1526, Owerri, Nigeria. 2 Polymer Technology Department, Auchi Polytechnic, PMB 13, Auchi, Nigeria. E-mail: mmchukwu@yahoo.com* ABSTRACT An investigation was carried out comparing seven different natural rubber formulations, in each case stearic acid level used varied from 0.00 pphr to 6.00 pphr. Vulcanizing at a temperature of 1650C

Send Inquiry

Vulcanization of elastomers

EBSCOhost serves thousands of libraries with premium essays, articles and other content including Vulcanization of elastomers. Get access to over 12 million other articles!

Send InquiryWhat is Vulcanized Rubber? (with pictures)

Vulcanized rubber is a natural elastomer that has been made more durable by a biochemical process that cures the rubber. During vulcanization, the milky latex from a rubber tree is combined with a curing ingredient — usually sulfur — and heated under pressure. This process, which was discovered by an American inventor named Charles Goodyear in 1839, made the rubber more stable, tougher and ...

Send Inquiry

Natural rubber

Natural rubber latex is shipped from factories in south-east Asia, South America, and West and Center Africa to destinations around the world. As the cost of natural rubber has risen significantly and rubber products are dense, the shipping methods offering the lowest cost per unit weight are preferred.

Send Inquiry

Vulcanization & Accelerators

Vulcanization & Accelerators Vulcanization is a cross linking process in which individual molecules of rubber (polymer) are converted into a three dimensional network of interconnected (polymer) chains through chemical cross links(of sulfur). The vulcanization process was discovered in 1839 and the individuals responsible for this discovery were

Send Inquiry

Vulcanization Accelerators - polymerdatabase.com

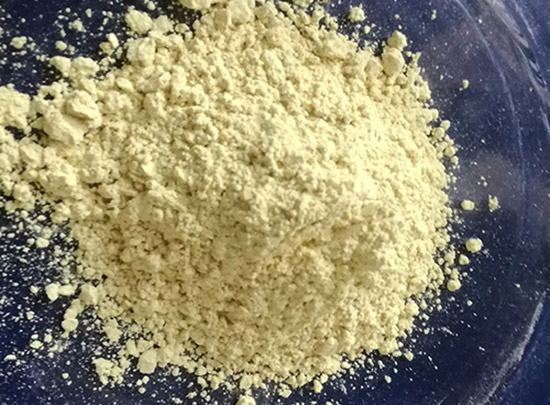

Vulcanization Accelerator. is a compound that increases the speed of vulcanization and that enables vulcanization to proceed at lower temperature and with greater efficiency. Vulcanization accelerators can be classified as primary and secondary accelerators. Important primary accelerators include thiazoles and sulfenamides.

Send Inquiry

Vulcanization

Vulcanization (British: vulcanisation) is a chemical process, invented by Charles Goodyear, used to harden rubber. Vulcanization traditionally referred to the treatment of natural rubber with sulfur and this remains the most common example, however the term has also grown to include the hardening of other (synthetic) rubbers via various means.

Send InquiryConveyor Belt Splicing And Vulcanization - ASGCO | ASGCO

Conveyor Belt Splicing and Vulcanization. ASGCO ® is a certified belt splicing company and continues to invest in the latest technology of vulcanizing presses and equipment to continually improve our conveyor belt splicing techniques. Our service technicians attend a certified conveyor belt splicing school certification class were they are trained in the latest splice procedures and material

Send InquiryChemGuide » rubber vulcanization accelerators

Research Summary: The report presents detailed overview of the Rubber Vulcanization Accelerators market in the world and regions (CIS countries in particular) by contemplating and analyzing its various parameters. Firstly, brief introduction is provided. Thus, rubber vulcanization accelerators properties, application areas and manufacturing technologies are considered.

Send Inquiry

To make intermediates in the manufacture of rubber

To make intermediates in the manufacture of rubber. To make intermediates in the manufacture of rubber vulcanization accelerators (MTB-2- Mercaptobenzothiazole). Production of Xanthates, Viscose Rayon Production and agriculture-Fumigant. Used in dehydration, separation, extraction and reaction applications.

Send Inquiry

Vulcanization of elastomers

EBSCOhost serves thousands of libraries with premium essays, articles and other content including Vulcanization of elastomers. Get access to over 12 million other articles!

Send InquiryEffect of Stearic Acid Level on the Physical Properties

PMB 1526, Owerri, Nigeria. 2 Polymer Technology Department, Auchi Polytechnic, PMB 13, Auchi, Nigeria. E-mail: mmchukwu@yahoo.com* ABSTRACT An investigation was carried out comparing seven different natural rubber formulations, in each case stearic acid level used varied from 0.00 pphr to 6.00 pphr. Vulcanizing at a temperature of 1650C

Send Inquiry